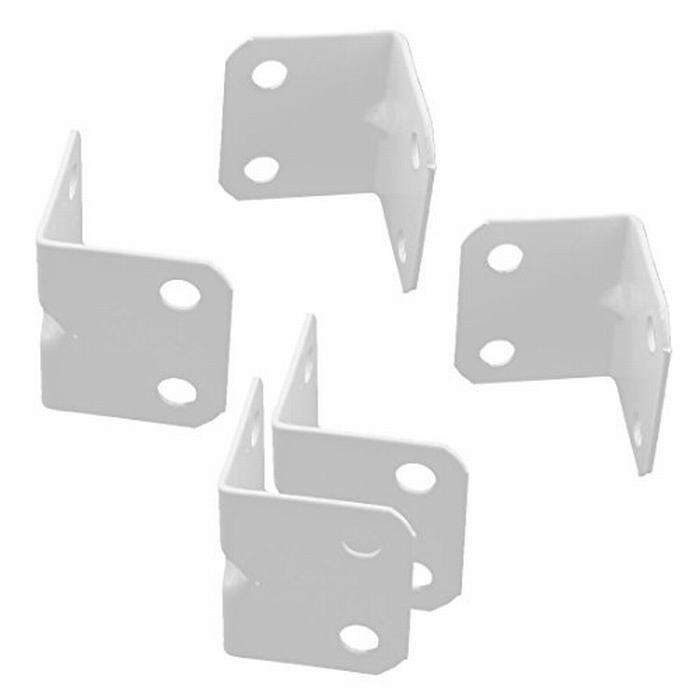

Professional Customized Service Galvanised Steel Stamping Shelf Bracket Sheet Metal Stamping Part

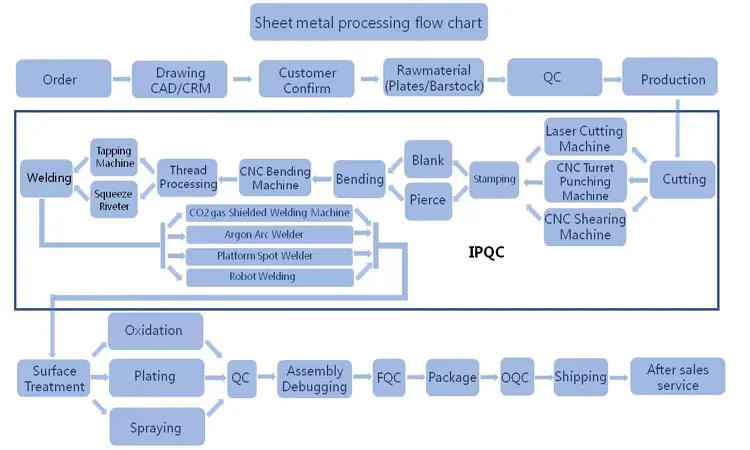

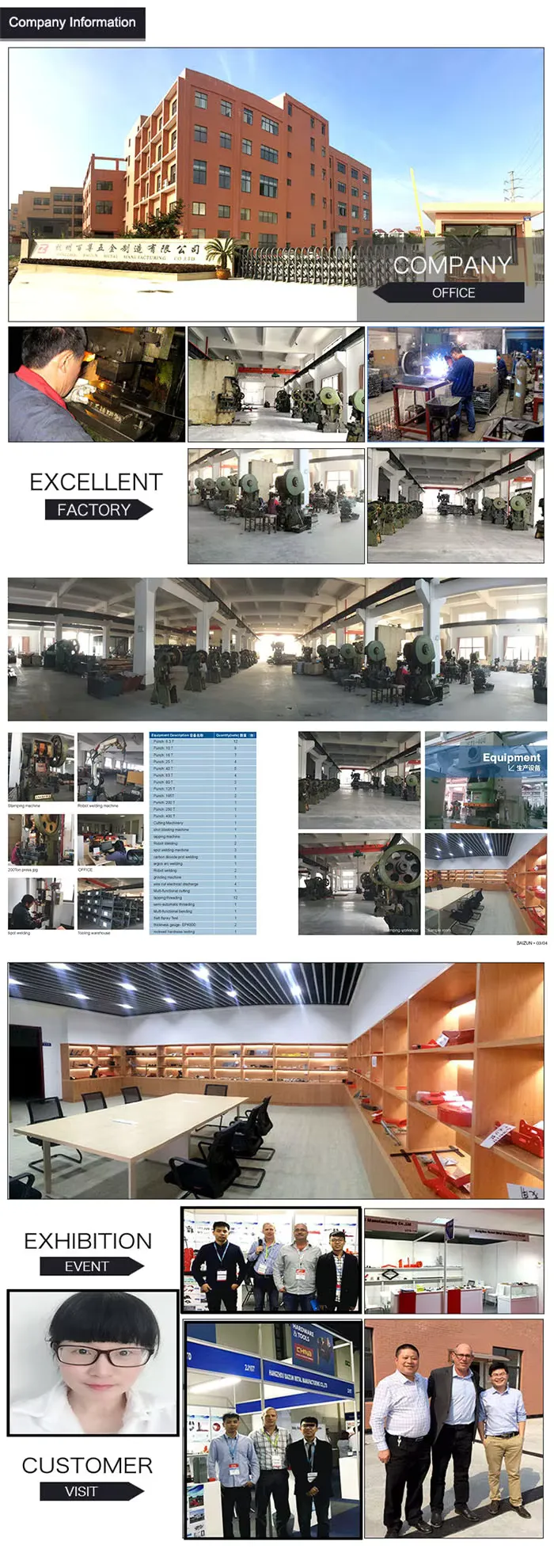

We offer professional customized services for galvanised metal stamping bracket in the form of high-precision sheet metal die stamping parts. These Steel Stamping Parts are developed with a focus on durability, flexibility, and dimensional accuracy, ideal for diverse industrial applications. We use advanced stamping techniques and high-strength galvanized steel to ensure each part performs under demanding conditions without compromise. From material selection to surface treatment, every stage of our process is tailored to deliver Steel Stamping Parts that meet complex design and structural requirements. Whether for prototyping or high-volume manufacturing, we support flexible customization, maintaining tight tolerances and consistent quality across batches.

Key attributes

Other attributes

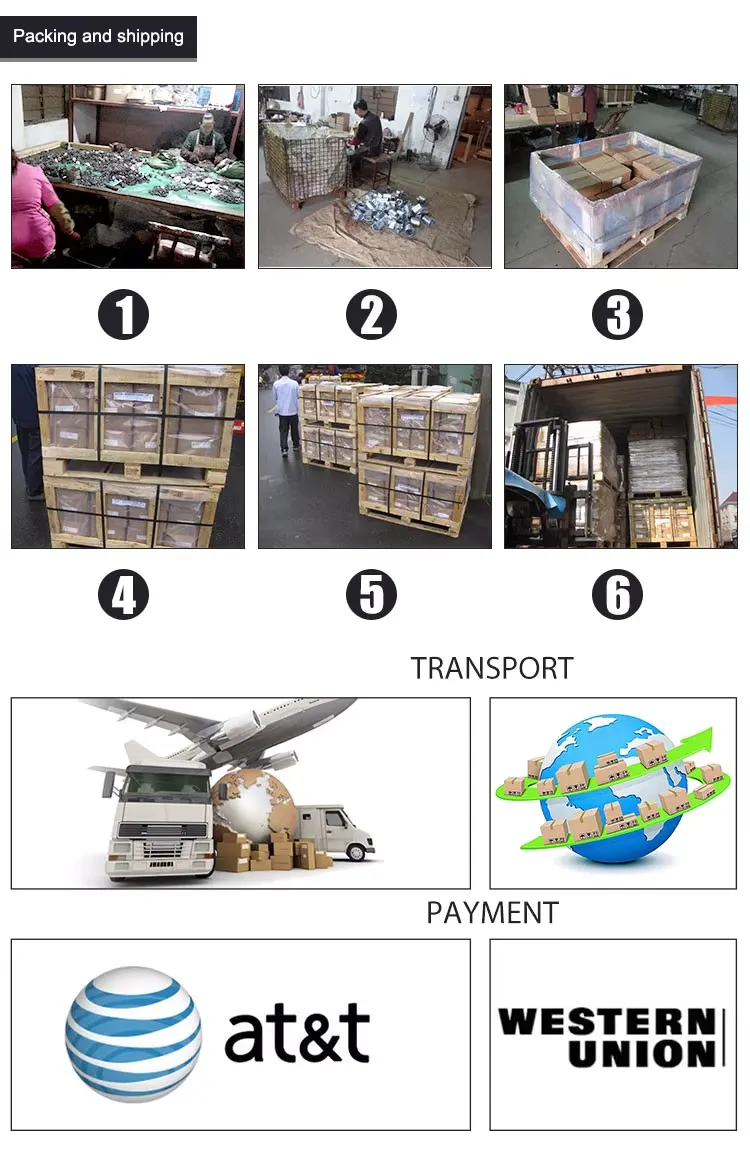

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Name | Professional Factory Customized OEM ODM Cnc Sheet Metal Stamping Car Production |

| Mold Life Time | 300K times |

| Product Material | 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Surface Treatment | Anodized, powder coating, lacquer coating, black oxide |

| Size | 1) According to customers' drawings 2) According to customers' samples |

| Drawing Format | step, dwg, igs, pdf |

| Certificates | ISO 9001:2015 |

| Payment Term | T/T, L/C, Trade Assurance |

1. Material Properties and Performance

We use galvanized steel plates as the base material for our Steel Stamping Parts due to their superior corrosion resistance, strength, and versatility. The zinc coating on the steel surface acts as a protective barrier, preventing rust and extending the service life of each stamped component. This characteristic makes our Steel Stamping Parts suitable for environments where moisture, chemicals, or exposure to the elements are present.

We carefully evaluate the thickness, coating adhesion, and flatness of the galvanized steel before production. These factors are critical to the success of precision stamping and bending. Our material performs well under mechanical stress and allows for consistent shaping during high-speed stamping operations. We rely on this material to achieve clean cuts, sharp angles, and uniform bends, reducing the chance of material fatigue or cracking over time.

The galvanized steel we use also improves surface smoothness, making it an excellent substrate for secondary surface finishes. Our Steel Stamping Parts retain both structural performance and aesthetic appearance even after extended use in complex assemblies or moving systems. We match the material properties with each client’s unique project needs, ensuring the final components meet expectations for both function and durability.

2. Manufacturing Capabilities and Customization

We specialize in the production of customized Steel Stamping Parts using a wide range of fabrication processes, including stamping, punching, bending, coining, notching, and flanging. Our machines are CNC-controlled and optimized for high precision and repeatability. We develop and maintain custom dies to meet specific geometric and mechanical requirements, allowing us to support both simple and complex part configurations.

We provide full customization services from design evaluation to mass production. Whether our clients supply technical drawings or performance specifications, we convert ideas into practical stamped solutions. We can incorporate holes, ribs, flanges, slots, and other features into Steel Stamping Parts, ensuring compatibility with downstream assembly or integration.

Multi-stage stamping is used for parts with high complexity or tight tolerances. We adjust press settings to achieve intricate shapes and functional features in a single workflow. This flexibility helps us reduce lead time and maintain part consistency. After stamping, we offer post-processing options such as deburring, polishing, and protective film application to enhance the final product’s quality and functionality.

Our customization approach ensures that each Steel Stamping Part fits precisely into its intended application, meeting both mechanical and aesthetic goals. We support various finishes and surface treatments to increase corrosion resistance, wear performance, and appearance, based on specific end-use environments.

3. Quality Control and Inspection Standards

We implement strict quality control procedures throughout the entire manufacturing cycle of our Steel Stamping Parts. Incoming galvanized steel is first inspected for coating integrity, flatness, and mechanical consistency. During stamping, we use inline monitoring systems to track force, alignment, and dimensional accuracy.

Each batch undergoes multiple inspections, including part-to-part comparison, surface consistency checks, and precision measurement using calibrated instruments. We verify that holes, bends, and edge features conform to technical drawings and that no burrs, distortions, or surface defects are present. For high-volume runs, we apply statistical process control (SPC) to track deviation trends and prevent defects before they occur.

We also conduct random sampling, tensile testing, and surface finish evaluations as required by the application. These steps ensure that every Steel Stamping Part we deliver meets strict functional and dimensional standards, reducing the risk of rework or field failure. Our inspection teams are trained to detect early-stage process deviations, allowing us to maintain quality and production efficiency simultaneously.

4. Industry Applications and Use Cases

Our Steel Stamping Parts are used across a wide range of industries due to their adaptability, strength, and precision. In the automotive sector, we provide stamped components for brackets, housings, mounting plates, and structural supports. In construction, our stamped parts are integrated into frameworks, wall panels, ceiling systems, and HVAC assemblies.

We also serve electrical equipment manufacturers, where Steel Stamping Parts are used in enclosures, switchgear supports, and panel interfaces. For furniture makers, our products support load-bearing functions and decorative elements. In the field of industrial machinery, our parts form essential links in control systems, protective casings, and equipment bases.

Because our process allows for flexible design, we can serve niche applications such as agricultural equipment, transportation, medical devices, and consumer appliances. Our Steel Stamping Parts are designed for performance consistency across diverse use cases, whether they operate in static, dynamic, high-load, or outdoor environments. Our approach prioritizes usability and integration, enabling seamless adoption across product categories.

5. Technical Equipment and Production Infrastructure

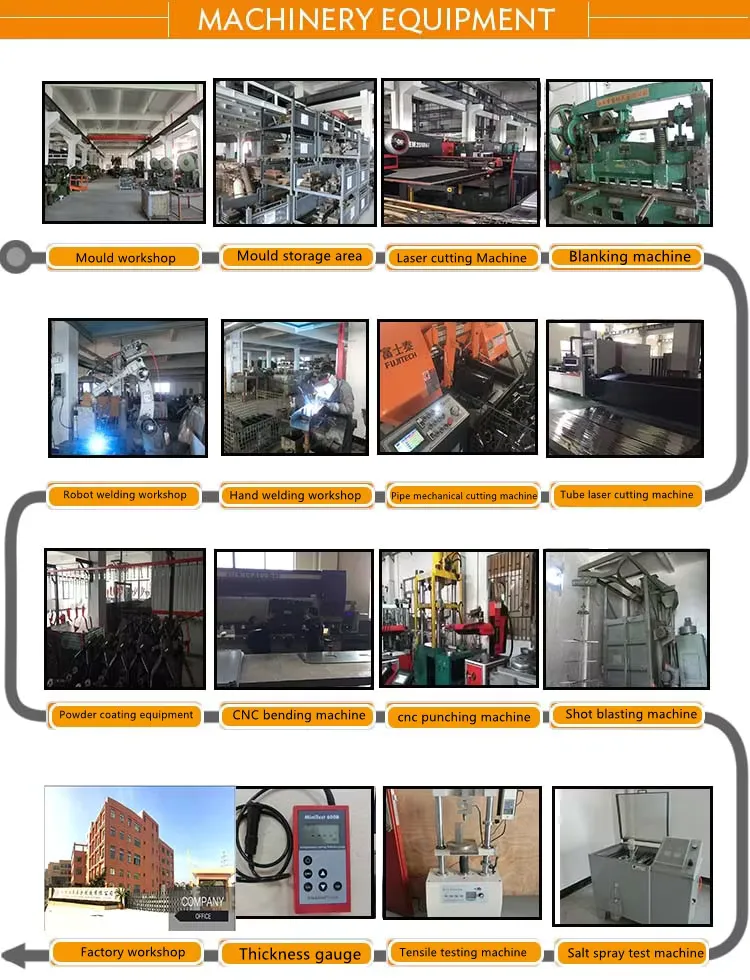

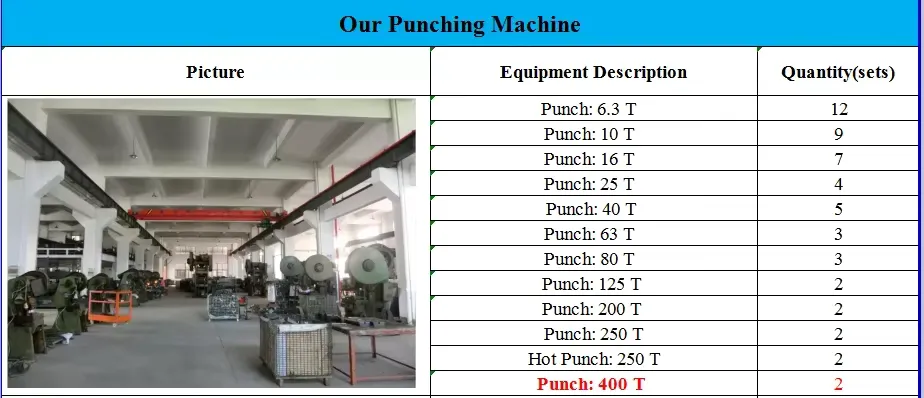

Our facility houses advanced equipment specifically tailored for producing Steel Stamping Parts with high accuracy and efficiency. We operate CNC stamping presses with programmable stroke lengths and pressure control, enabling us to handle various material thicknesses and geometries. We also use progressive die setups for complex parts requiring multiple operations in a continuous sequence.

We invest in tooling precision, using high-grade steel for dies and maintaining strict tolerances to ensure clean repeatability across thousands of cycles. Our bending machines support multi-angle and complex radius bending, while our notching and coining systems allow us to create detailed features without secondary machining.

In addition to core stamping machines, we operate auxiliary systems for material feeding, part ejection, and in-line quality monitoring. These integrations enhance cycle times and reduce material waste. We also maintain an in-house tooling department, allowing for quick mold changes and faster development of new Steel Stamping Parts.

Our production is supported by digital design and simulation software, enabling pre-production validation and modification of part geometries. We continuously upgrade our systems to match evolving industry standards, ensuring that our Steel Stamping Parts meet the highest benchmarks for efficiency and quality across all production stages.