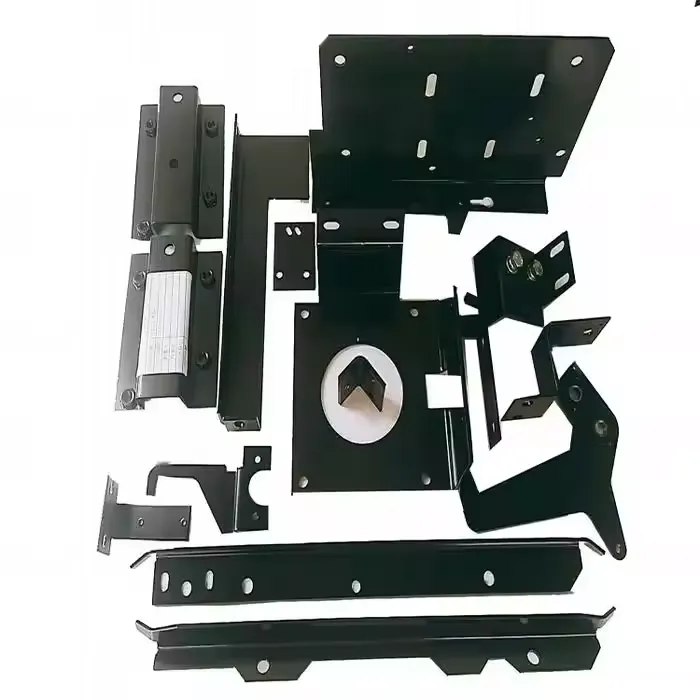

Custom Laser Cut Works Stainless Steel Aluminum Stamping Bending Welding Metal Sheet Parts

We offer customized laser cut works specializing in stainless steel stamping parts and aluminum components. Our service includes precise bending, welding, and fabrication of metal sheet parts tailored to meet diverse industrial requirements. Through advanced laser cutting technology, we ensure high accuracy and clean edges in every stainless steel stamping part, enhancing both functionality and aesthetic appeal.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Our custom laser cutting service covers stainless steel stamping parts widely used in automotive, electrical, construction, and machinery industries. The combination of laser cutting with bending and welding allows us to produce complex and robust metal assemblies.

Stainless steel stamping parts are manufactured with high precision to guarantee dimensional accuracy and consistent quality. We select suitable stainless steel and aluminum materials to meet performance requirements, emphasizing corrosion resistance and mechanical strength.

Bending and welding processes enhance the structural integrity of metal sheet parts. Throughout production, strict process controls are implemented to maintain product quality without excessive emphasis on inspection.

Clients can customize parameters such as dimensions, thickness, and surface treatment to meet project needs. Options like polishing or passivation improve aesthetics and environmental resistance.

Our capabilities support both prototype development and mass production, offering flexible scheduling for urgent and complex orders. The laser cut stainless steel stamping parts produced are applicable in metal enclosures, brackets, frames, and other industrial components.

By combining laser cutting with expert bending, welding, and sheet metal fabrication, we deliver stainless steel stamping parts that fit precisely and perform reliably. Ongoing improvements ensure alignment with evolving industry standards and customer expectations in metal stamping.