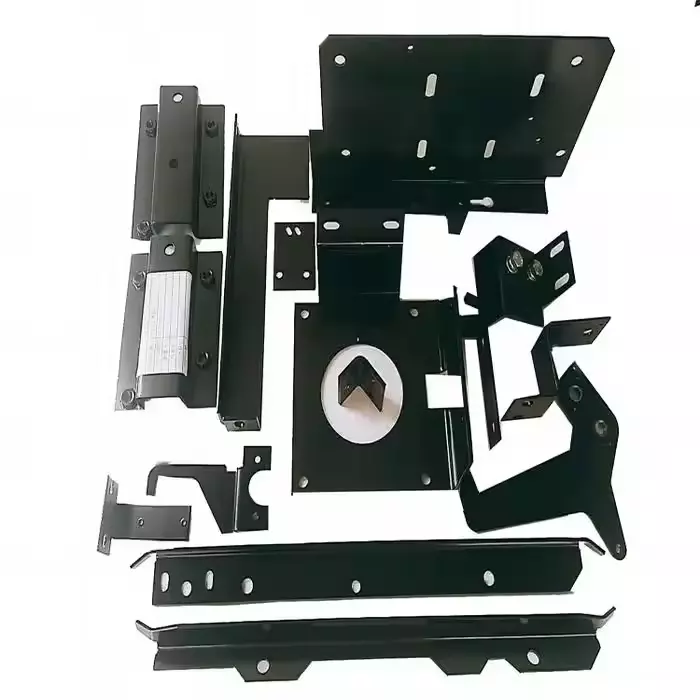

Customized Oem Precision Sheet Metal Forming Parts Metal Bending Part Irregular Metal Stamping Parts

We provide comprehensive solutions for irregular metal stamping parts, focusing on precision, complexity, and customization through advanced metal stamping forming techniques. Our services are tailored to accommodate unique shapes, contours, and functions, enabling us to meet a broad spectrum of industry demands. The core of our metal stamping forming approach lies in adapting to irregular designs while ensuring mechanical stability and repeatability.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Product Description

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

We provide comprehensive solutions for irregular metal stamping parts, focusing on precision, complexity, and customization through advanced metal stamping forming techniques. Our services are tailored to accommodate unique shapes, contours, and functions, enabling us to meet a broad spectrum of industry demands. The core of our metal stamping forming approach lies in adapting to irregular designs while ensuring mechanical stability and repeatability.

1. Customized Metal Stamping Forming for Complex Shapes

We specialize in metal stamping forming for components with non-standard geometries. Irregular shapes often require multi-directional deformation, non-uniform material distribution, and precision alignment. Our team addresses these complexities by utilizing high-accuracy dies and flexible forming methods. Through iterative tooling and design refinement, we provide reliable metal stamping forming even for highly asymmetric or multi-layered parts. This capability is crucial in sectors such as automotive interiors, enclosures, medical equipment, and smart devices.

2. Adaptability to Multiple Material Types and Thicknesses

Irregular metal stamping parts often require compatibility with various materials, including stainless steel, aluminum, and carbon steel. Our metal stamping forming process accommodates these differences with controlled pressure, speed, and die design. By fine-tuning each forming cycle, we maintain dimensional accuracy regardless of material type. The metal stamping forming process also ensures minimal stress concentration, avoiding deformation issues in thin or uneven substrates. We adjust forming strategies depending on each project’s physical requirements.

3. Integration of Stamping and Secondary Processing

We combine metal stamping forming with other processes such as welding, deburring, tapping, and assembly. Irregular components typically involve complex transitions and connection points that must be reinforced or processed after stamping. Our integrated workflow ensures that every metal stamping forming project moves seamlessly from blanking to finishing, minimizing production gaps. This approach improves production efficiency and shortens lead times, particularly when dealing with parts that demand secondary shaping, openings, or curved contours.

4. Engineering Design Support for Irregular Applications

We offer collaborative engineering support from the design phase onward. For irregular metal stamping parts, early-stage design input is crucial to identify forming limits, avoid excessive stress points, and ensure manufacturability. Our team applies simulation software to test metal stamping forming feasibility before production. This predictive modeling allows us to identify weak zones, optimize tooling layout, and reduce waste. Through this support, clients gain enhanced control over development cost and performance.

5. Scalable Metal Stamping Forming for High-Mix Orders

Our facility supports low-to-high volume runs of irregular components without compromising metal stamping forming consistency. Many irregular designs are used in modular systems or specialized equipment, which require flexible order quantities. We apply modular tooling systems and batch scheduling to streamline transitions between projects. The metal stamping forming setup is optimized to allow rapid changeovers and minimal downtime, ensuring efficient processing of both prototyping and bulk production.

6. Surface Treatment Options Post-Metal Stamping Forming

After forming, we provide multiple surface finishing options to enhance corrosion resistance, appearance, and adhesion properties. These include powder coating, electroplating, anodizing, and oiling, all compatible with the metal stamping forming workflow. We ensure that post-processing does not affect the structural integrity of irregular parts. Each finishing step is tailored to suit the metal stamping forming stage and final application conditions.