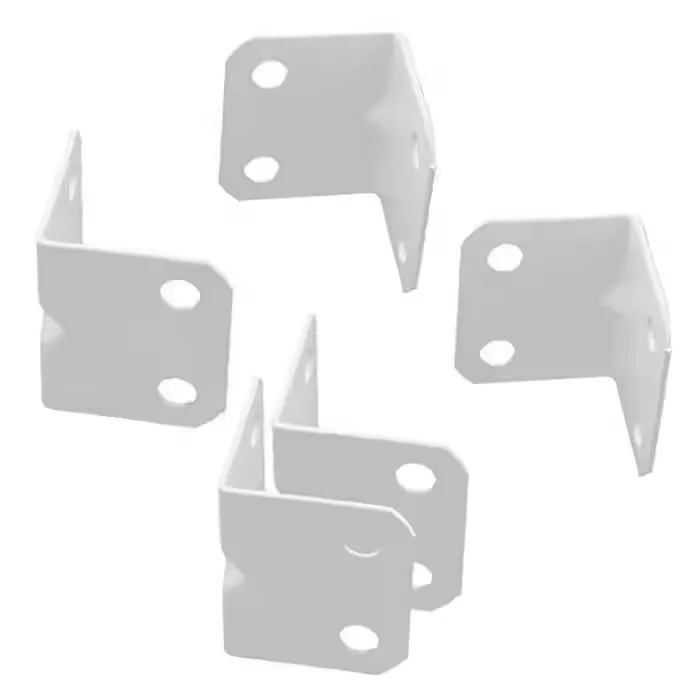

Factory Customized Steel Stamping Deep Drawing Tractor Sheet Metal Parts

We specialize in factory-customized steel stamping and deep drawing services tailored for tractor sheet metal parts. Our capabilities enable precise forming of complex shapes with high repeatability, meeting the demanding requirements of agricultural machinery components. The combination of stamping and deep drawing ensures enhanced strength and durability in the finished parts.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Advanced Stamping and Deep Drawing Processes

We use advanced equipment to deliver precise sheet metal stamping parts, ensuring consistency for tractor applications. Our deep drawing methods expand the capabilities to form intricate parts beyond basic stamping limits.

Material Handling and Optimization

We mainly work with steel, adjusting the stamping and deep drawing parameters to maintain material strength and surface finish. This approach supports the production of sheet metal stamping parts that perform well in demanding environments.

Custom Tooling and Flexible Production

Our customized tooling supports the fabrication of sheet metal stamping parts tailored to client designs. We adapt manufacturing to different volumes, ensuring flexibility and precision throughout production.

Combination of Secondary Operations

In addition to stamping and deep drawing, we provide related services such as trimming and forming. These integrated steps allow the delivery of ready-to-install tractor sheet metal parts.

Focus on Functional and Structural Requirements

We prioritize producing sheet metal stamping parts with proper strength, shape accuracy, and surface quality to meet industry standards for agricultural machinery.

Wide Application Scope

Our products serve multiple tractor components including brackets, covers, and chassis parts. The sheet metal stamping parts are designed to fit specific mechanical and environmental needs.

Reliable Workflow and Timely Delivery

We maintain a stable manufacturing process to ensure sheet metal stamping parts are produced on schedule. Our commitment is to deliver parts that align with customer expectations and project timelines.