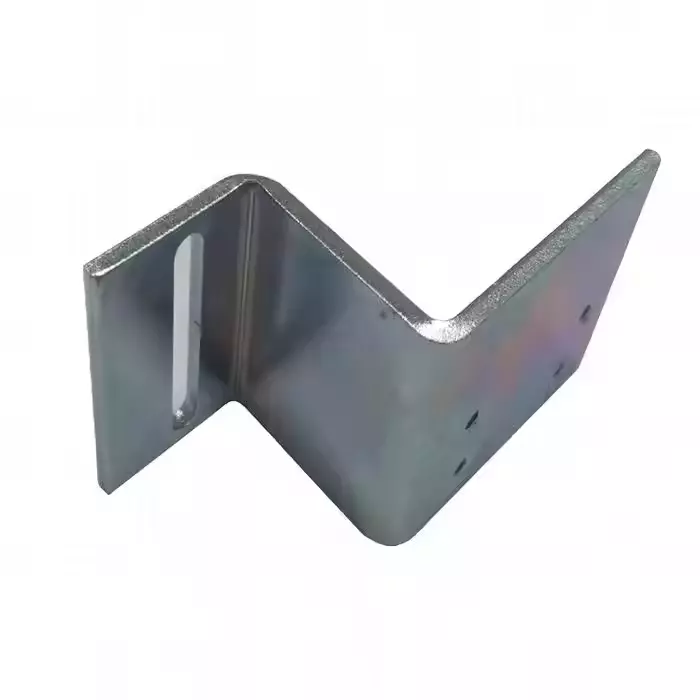

Factory Professional High Precision Sheet Metal Stamping Processing Steel Stampng Brackets

We offer professional factory-grade high precision sheet metal stamping processing services, specializing in the production of steel stamping brackets. Our expertise lies in delivering Custom Sheet Metal Stamping Products with exceptional accuracy, durability, and reliability to meet diverse industrial requirements.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

Advanced Sheet Metal Stamping Technology

Our high precision sheet metal stamping processing utilizes state-of-the-art machinery capable of producing complex and precise steel stamping brackets. The technology ensures that every Custom Sheet Metal Stamping Product achieves exact dimensions and fine surface finishes, minimizing material waste and optimizing production efficiency.

Material Selection and Compatibility

We carefully select high-quality steel materials suitable for sheet metal stamping brackets, balancing strength and machinability. Our Custom Sheet Metal Stamping Products benefit from materials that provide superior load-bearing capacity and resistance to wear, ensuring long service life even under demanding conditions.

Precision in Forming and Stamping

The stamping process involves precise tooling and dies designed for each Custom Sheet Metal Stamping Product. Our manufacturing line controls tolerances strictly to maintain uniformity across batches. This precision guarantees that steel stamping brackets fit perfectly in assemblies and perform their intended mechanical functions effectively.

Surface Treatment and Finishing

Post-stamping, we offer a variety of surface treatments such as powder coating, galvanizing, and plating to enhance corrosion resistance and aesthetic appeal. These finishing processes improve the durability of Custom Sheet Metal Stamping Products and make them suitable for different environmental exposures, including harsh industrial settings.

Quality Assurance and Inspection

Quality control is integrated at every stage of our sheet metal stamping processing. We implement dimensional inspections, hardness tests, and stress analysis to ensure each steel stamping bracket meets stringent standards. This thorough quality assurance guarantees consistent performance and reliability for all Custom Sheet Metal Stamping Products.

Versatility and Industry Applications

Our Custom Sheet Metal Stamping Products are designed for diverse applications including automotive components, industrial machinery, electronics, and construction. The adaptability of our high precision sheet metal stamping processing allows us to meet varied client specifications and volume requirements efficiently.