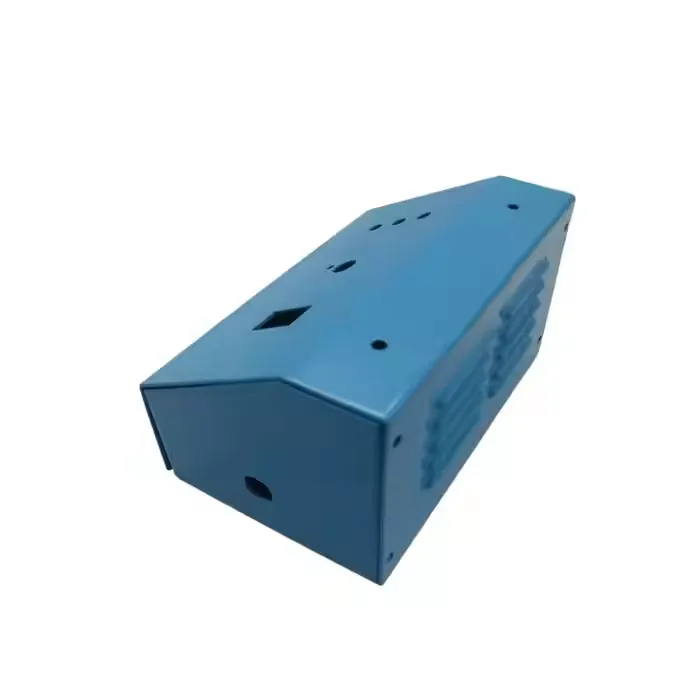

High Precision Staming And Punching Stainless Steel Aluminum Sheet Metal Punching Parts

We offer high precision stamping and punching services for stainless steel and aluminum sheet metal, specializing in delivering precise metal stamping components. Our precision metal stamping processes ensure accuracy and consistency in producing sheet metal punching parts for diverse industrial applications.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Surface treatment for different material parts:

Our precision metal stamping process utilizes advanced machinery capable of handling a wide range of stainless steel and aluminum sheet thicknesses. This ensures the production of consistent, high-quality stamped parts designed to meet stringent specifications. Precision metal stamping allows us to perform diverse operations such as blanking, piercing, forming, and deep drawing with exceptional accuracy.

Throughout the stamping and punching stages, we emphasize strict quality control measures to maintain dimensional stability and surface integrity. Our precision metal stamping service supports flexible batch sizes—from small prototype runs to high-volume production—while maintaining repeatability and reliability.

Additional finishing options, including polishing, coating, or heat treatment, can be incorporated to enhance the durability and appearance of the stamped metal components. We closely collaborate with clients to optimize part designs for manufacturability and cost-effectiveness, ensuring that each precision metal stamping project meets exact functional and aesthetic requirements.

Our expertise in precision metal stamping extends across industries such as automotive manufacturing, agricultural machinery, electronics, and heavy equipment. We continuously invest in technology and process improvements to maintain a competitive edge in delivering precision metal stamping solutions that satisfy diverse industrial demands.