Metal Work Factory Sheet Metal Parts Stamping & Plating & Welding & Laser Cutting Service

We specialize in providing one-stop solutions as laser cut metal fabricators, offering comprehensive capabilities that include stamping, plating, welding, and laser cutting for sheet metal parts. Our team supports diverse industrial demands by tailoring each fabrication project to exact application needs. Through a wide range of material processing methods, we aim to deliver consistent performance across structural, decorative, and functional components.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Material Processing Expertise

As laser cut metal fabricators, we apply advanced CNC laser technology to cleanly cut through a wide range of materials with minimal edge deformation. Our services cover stainless steel for its corrosion resistance, aluminum for its lightweight properties, and carbon steel for its structural reliability. These materials are prepared using consistent calibration and layout methods to ensure precision before any stamping or plating takes place.

Our team ensures accurate laser kerf control, allowing for seamless integration of laser cutting with subsequent bending, forming, or welding steps. This enables us to produce consistent laser cut metal fabricators outcomes even for intricate assemblies or multi-surface interfaces.

Functional Fabrication Capabilities

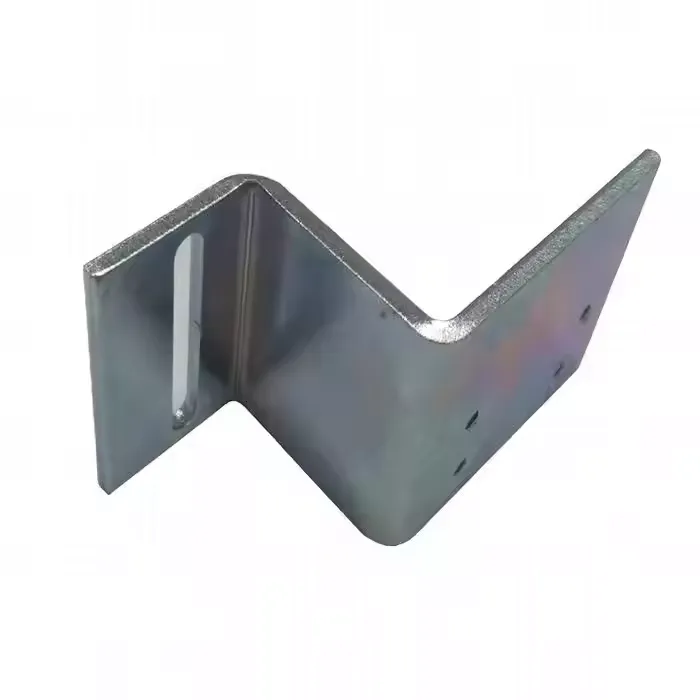

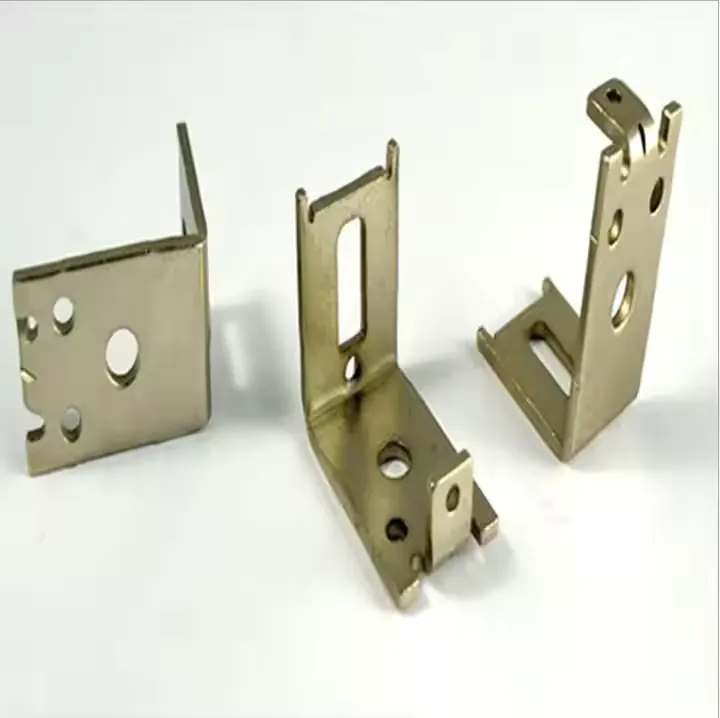

We integrate laser cutting with traditional stamping to produce highly functional components for enclosures, brackets, housings, and reinforcement plates. Our approach to laser cut metal fabricators ensures excellent surface uniformity, structural accuracy, and dimensional repeatability.

Each part benefits from design flexibility—tight internal cutouts, rounded profiles, or mounting holes can all be integrated within the same workflow. Our fabrication methods support interlocking parts, folded corners, and multi-layer assemblies that require both strength and aesthetic consideration.

Custom Applications Across Industries

We work closely with clients across electronics, automotive, machinery, construction, and furniture sectors. As laser cut metal fabricators, we design each metal part to meet unique application requirements, including support frames for mechanical assemblies, protective cases for electrical systems, and frames for structural modules.

No matter the batch size, we maintain consistent production logic that accommodates low-variation, high-efficiency workflows. Our service supports customization at various scales without compromising quality control standards.

Surface Preparation and Welding Integration

Once laser cut, components can undergo additional treatments such as plating, powder coating, or surface smoothing, depending on their intended use. For assemblies, we provide MIG/TIG welding integration using jigs and fixtures to ensure alignment and durability.

We prioritize weld-ready designs from the start, allowing laser cut metal fabricators steps to align with the final assembled structure. This approach minimizes misalignment during production and contributes to better fitting parts in real-world applications.

Processing Flexibility and Part Optimization

Our strength lies in adapting each workflow to meet part-specific tolerances and features. Whether it's curved profiles, open slots, layered plates, or low-profile ribs, our laser cut metal fabricators processes deliver precise shapes without excess waste or rework.

In support of modern product design, we also optimize laser parameters for material type and part function. That means cleaner edges for visible parts, tighter tolerances for mechanical fits, and consistent cut quality for parts requiring post-processing.

Service Coverage

We provide services to clients across industrial hubs in Asia, Europe, and North America. Our facility accommodates both one-off prototypes and long-term manufacturing partnerships for diverse custom metal needs.