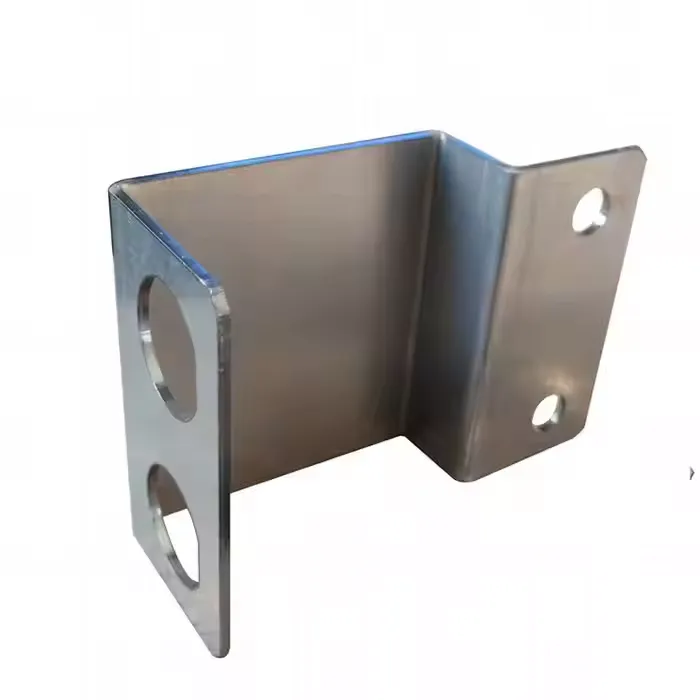

OEM Factory Custom Stamped Processing Service Aluminum Iron Brass Metal Stamping Parts

We specialize in producing aluminum stamping parts tailored to meet diverse application demands across industries such as electronics, lighting, furniture, and automotive. With a deep understanding of metal deformation behavior and material response under force, we transform aluminum sheets into precise shapes through advanced stamping techniques. Our services integrate flexibility, precision, and consistency for both low-volume prototypes and high-volume production runs.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Product Description

Optimized Metal Forming Capabilities

We handle stamping tasks for aluminum, iron, and brass materials, offering efficient conversion from raw sheet stock into precise component shapes. Our experience in working with non-ferrous alloys allows us to deliver aluminum stamping parts with tight tolerances, uniform wall thickness, and enhanced edge quality.

Advanced Tooling for Aluminum Alloys

Our dies are engineered for optimal compatibility with aluminum’s ductility and work-hardening characteristics. We configure press parameters, die clearances, and stroke speeds specifically to reduce cracking, wrinkling, and springback in finished aluminum stamping parts, ensuring structural reliability.

Controlled Process Sequencing

We implement blanking, forming, piercing, and flanging in a single press operation whenever possible. This reduces handling time and minimizes deformation risks. Every aluminum stamping part produced through this integrated sequence exhibits consistency in size, geometry, and material response.

Clean Edge Formation and Surface Uniformity

To maintain high-quality finishes, we utilize precision shearing and burr-removal protocols. Our aluminum stamping parts are processed to prevent edge fatigue and are prepared for downstream steps such as surface coating or mechanical fastening.

Lightweight, High-Strength Performance

Aluminum’s strength-to-weight ratio makes it ideal for functional components requiring durability without mass burden. We create aluminum stamping parts that support weight reduction targets while maintaining impact resistance, thermal stability, and load-bearing properties.

Geometry Customization for Functional Applications

We produce flat and 3D-formed aluminum stamping parts with features such as flanges, countersinks, holes, ribs, and slots, all of which are tailored to their assembly environments. These shapes improve fitment, airflow, rigidity, and integration within mechanical systems.

Reliable Output at Scale

Whether producing small brackets or large mounting plates, we maintain consistency through automated feed systems and real-time press monitoring. This ensures that each aluminum stamping part conforms to dimensional standards, even in long production runs.

Enhanced Compatibility with Finishing Processes

Each aluminum stamping part is designed to accommodate post-stamping processes like powder coating, anodizing, riveting, or welding. Dimensional stability and clean surfaces ensure that final finishing yields optimal adhesion and aesthetics.

Multi-Industry Applications

Our aluminum stamping parts are widely used in enclosures, panel structures, ventilation covers, and machine interfaces. Industries such as telecommunications, building systems, and agricultural machinery frequently rely on these components for structural and aesthetic roles.

Technical Consultation and Design Optimization

We support design improvements for cost-effective manufacturing and better mechanical performance. By evaluating the geometry and production pathway, we help reduce stress concentrations, material waste, and production cycle times for each aluminum stamping part.