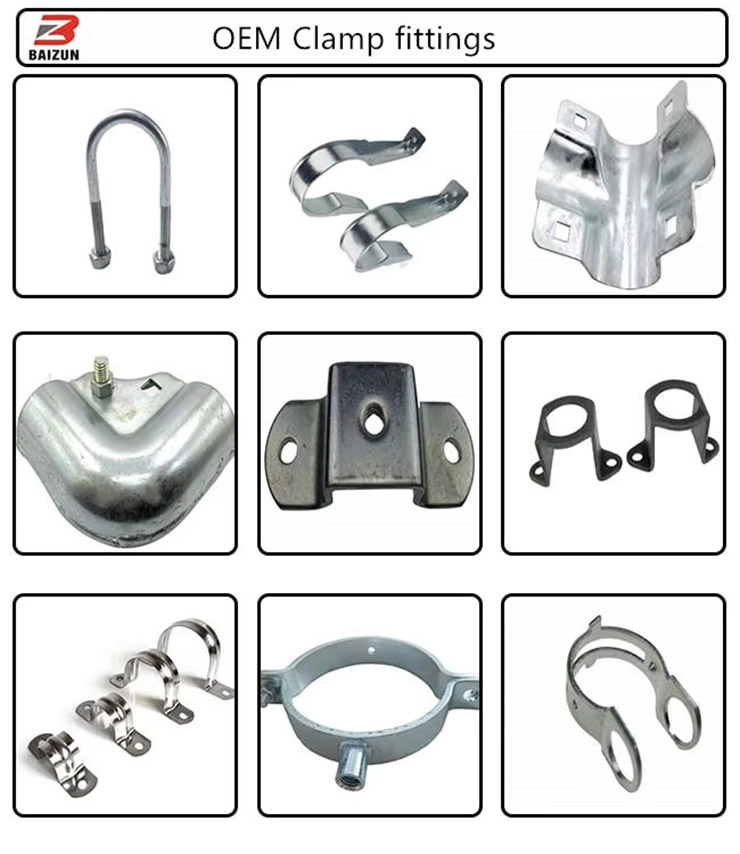

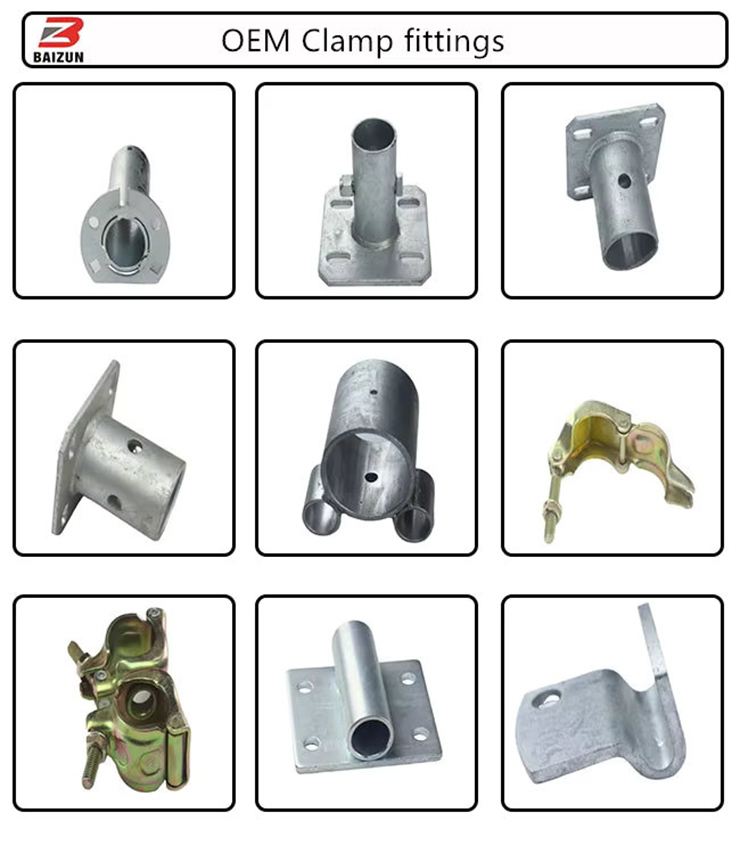

Wholesale Metal Stamping Service Stainless Steel Metal Stamping Fence Pipe Clamp

Metal Stamping Service plays a crucial role in the mass production of precision components, particularly in the development of stainless steel fence pipe clamps. These products serve structural and fastening purposes across a wide variety of industrial and residential applications. Utilizing advanced tooling, press operations, and quality inspection systems, Metal Stamping Service transforms flat metal into complex, reliable forms tailored for mechanical and architectural uses.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Features

| Materials | 1) AL1060, AL6061, AL6061, AL5052 etc. 2) Steel, mild steel, SPCC etc. 3) SS201, SS303, SS304, SS316, SS316L etc. 4) SPTE, galvanized sheet etc. 5) Brass, copper etc. |

| Specification | 1) According to customers' drawings 2) According to customers' samples |

| Usage | Agriculture Machinery, Farms, Furniture, Power, Appliance, Auto, Building, Solar Energy, Instrumentation, Medical device. |

| Mold Material | Cr12 |

| Mfg Process | Mold Make,Laser Cutting, bending, stamping/punching, welding,Assembly ,Packing. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Drawing format | DWG, DXF, Stp, Igs, PDF, Jpg, etc. |

| Service Type | OEM&ODM |

Metal Stamping Service plays a crucial role in the mass production of precision components, particularly in the development of stainless steel fence pipe clamps. These products serve structural and fastening purposes across a wide variety of industrial and residential applications. Utilizing advanced tooling, press operations, and quality inspection systems, Metal Stamping Service transforms flat metal into complex, reliable forms tailored for mechanical and architectural uses.

1. Precision Forming Technology in Pipe Clamp Manufacturing

One of the core elements of Metal Stamping Service lies in its ability to deliver high-precision results through controlled die and press operations. Stainless steel fence pipe clamps, with their curved, contoured geometry, demand consistent repeatability. This is only achievable through a well-managed stamping process. The presses used in Metal Stamping Service provide the force necessary to mold stainless steel into complex clamp designs, ensuring that dimensions remain accurate across thousands of production cycles.

Such high precision is vital for maintaining proper fitment when these clamps are attached to fencing frameworks, tubes, or structural pipes. Variability in clamp geometry could result in assembly issues, which is why manufacturers rely on experienced Metal Stamping Service providers to meet tight tolerances and mechanical integrity standards.

2. Stainless Steel: Durability Meets Versatility

The selection of stainless steel in this context is strategic, due to its strength, corrosion resistance, and long service life. Metal Stamping Service applied to stainless steel allows the clamp to retain mechanical integrity under stress while withstanding environmental exposure without rusting or deforming. These characteristics are especially critical in outdoor installations, where the pipe clamp may be exposed to rain, humidity, UV, and physical load.

Moreover, stainless steel offers excellent formability in stamping processes. Through controlled press operations, Metal Stamping Service delivers consistent shapes while maintaining the material’s internal grain structure. This ensures that even after multiple bends or forming steps, the clamps remain crack-free and maintain performance for long-term use.

3. Functional Design for Fencing and Pipe Securing

The functional utility of the fence pipe clamp depends heavily on a thoughtful design combined with accurate execution from the Metal Stamping Service. A well-designed clamp must grip pipes firmly without causing surface damage or slippage. This involves smooth edges, uniform curvature, and consistent thickness—all of which are made possible through systematic stamping methods.

These clamps are used in securing fencing panels to structural posts or horizontal rails. They may also serve as attachment points for signs, barriers, or netting systems. The reliability of the Metal Stamping Service ensures that each piece maintains equal clamping force and performs effectively under tension or vibration without loosening.

4. Cost-Efficient Large-Scale Production

One of the defining advantages of Metal Stamping Service is the scalability of production. Once tooling is prepared, hundreds or even thousands of stainless steel fence pipe clamps can be manufactured rapidly with minimal material waste. This allows for price stability and competitive supply across wholesale markets.

In bulk orders, cost per unit decreases significantly, making Metal Stamping Service an ideal choice for volume-based projects such as infrastructure installations, agricultural fencing, urban security enclosures, and utility frameworks. The ability to maintain consistent product quality while scaling up volume is a significant factor in industry adoption.

5. Surface Integrity and Post-Processing Compatibility

In addition to forming, Metal Stamping Service enables the creation of parts that are compatible with post-processing treatments. Stainless steel fence pipe clamps may undergo surface smoothing, cleaning, or protective finishing such as passivation. The initial stamping process prepares the surface for such enhancements by avoiding burrs, sharp edges, or contamination.

Post-stamping inspections are integrated into the Metal Stamping Service workflow to ensure that parts are free from defects like warping, deformation, or incomplete formations. These checks play a key role in maintaining consistency and preventing downstream rework. Once stamped and verified, clamps are ready for direct packaging or additional finishing based on customer needs.