China Professional Custom Metal Parts Supplier Stainless Steel Aluminum Sheet Metal Laser Cutting Service

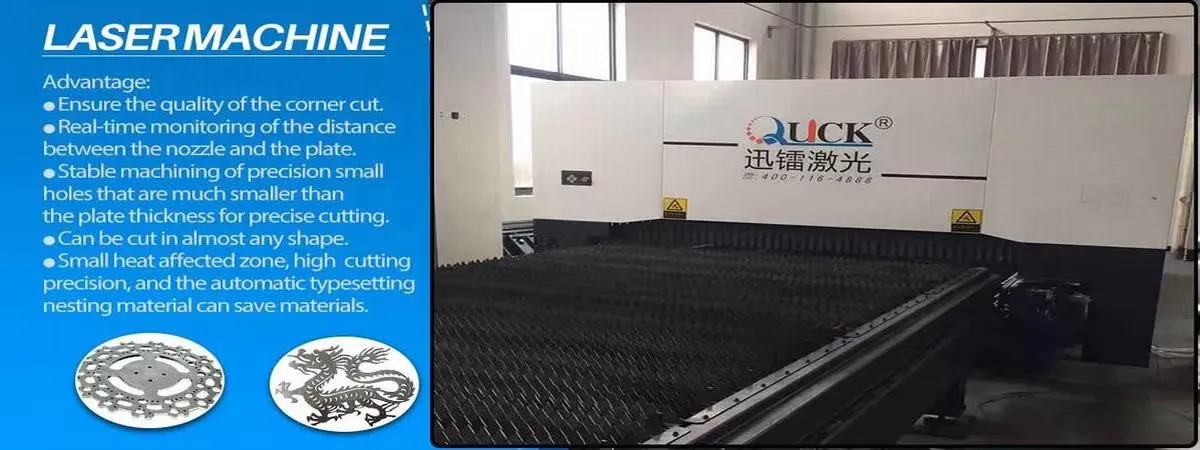

We focus on delivering high-performance custom laser cutting parts solutions for stainless steel, aluminum, and other sheet metal materials. Our services are engineered to meet demanding requirements across industries by combining advanced laser cutting technology with flexible production capabilities. With deep experience in working with sheet metal components, we specialize in the production of custom laser cutting parts for applications that demand precision, consistency, and adaptability.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Our advantage for metal fabrication a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience | |

| Materials | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

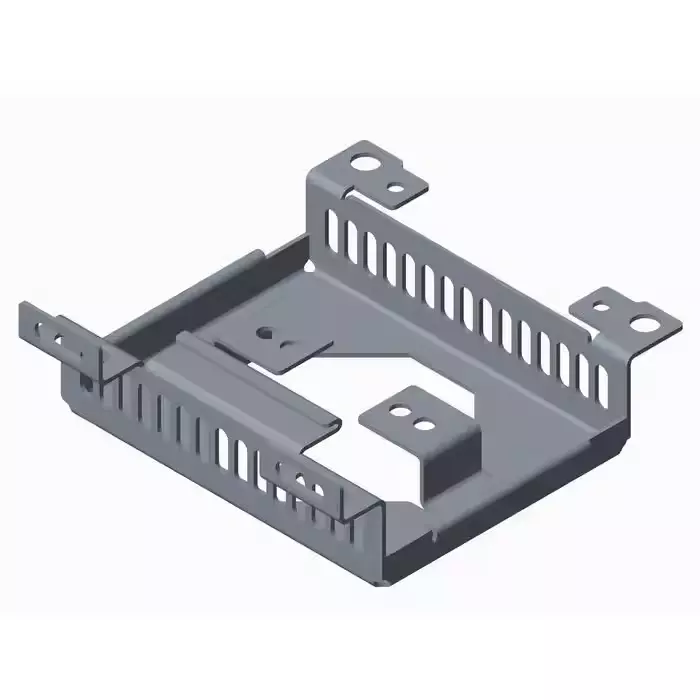

1. Precision Engineering for Complex Custom Laser Cutting Parts

We are committed to producing custom laser cutting parts that meet the exacting tolerances and design standards required in today’s market. Our high-precision cutting systems ensure clean, burr-free edges and excellent repeatability across both small and large batches. Whether it’s intricate internal profiles, fine cut-outs, or complex external contours, we ensure that every custom laser cutting part matches the CAD design accurately. These capabilities allow us to support industries including automotive, electronics, industrial enclosures, and smart devices.

2. Compatibility with a Wide Range of Sheet Metals

We work with a variety of materials when producing custom laser cutting parts, especially stainless steel and aluminum sheets. These materials offer corrosion resistance, aesthetic appeal, and strength-to-weight benefits, making them suitable for structural and decorative applications. Our team understands the unique thermal behavior of different metals during the laser cutting process and adjusts parameters to prevent edge hardening, warping, or discoloration. Each custom laser cutting part maintains its mechanical integrity and surface finish regardless of material type.

3. Flexible Production for High-Mix, Low-to-High Volume Orders

Our facility supports a wide range of order volumes for custom laser cutting parts—from prototypes and trial samples to medium and large-scale production. Using modular programming and automated nesting, we optimize material utilization while ensuring cost-effective production. We can switch between material types, thicknesses, and part geometries efficiently, allowing our clients to order diversified custom laser cutting parts without delays. This flexibility is key for clients requiring multiple versions of a component across different assemblies.

4. Integration of Post-Processing Services

We offer downstream services such as deburring, tapping, bending, welding, and surface treatments to complement our custom laser cutting parts. After the laser cutting process, parts often require additional steps to prepare them for assembly or end use. By providing integrated processing, we reduce handling time, ensure dimensional stability, and maintain production consistency. We carefully manage the interface between laser cutting and secondary processes to maintain the quality of every custom laser cutting part.

5. Design Optimization and Technical Support

We assist clients in refining their designs for custom laser cutting parts, ensuring they are both manufacturable and functionally optimized. Our engineering team analyzes drawings, offers material recommendations, and validates designs using simulation tools when needed. We identify potential cutting challenges and offer adjustments that maintain the core function while reducing production costs or complexity. This proactive collaboration enables us to enhance the performance and consistency of every custom laser cutting part.

6. Surface Finishing Solutions for Custom Laser Cutting Parts

After laser cutting, many custom laser cutting parts require surface treatments to improve corrosion resistance, electrical conductivity, or aesthetic value. We offer a range of finishes including powder coating, anodizing, passivation, and painting. Each treatment is applied based on the part’s application and environment, without compromising tolerance or shape. This compatibility between surface treatment and cutting quality ensures each custom laser cutting part is ready for direct application.

7. Diverse Applications Across Key Sectors

Our custom laser cutting parts are used in sectors such as construction, automotive frames, electrical housings, smart home devices, mechanical assemblies, agricultural machinery, and more. The adaptability of our process allows us to cater to projects that vary significantly in size, function, and complexity. By understanding end-use requirements, we align our laser cutting strategy to maximize usability and service life of the finished custom laser cutting parts.

8. Quality Control Throughout the Laser Cutting Workflow

We apply strict quality control at every stage of custom laser cutting parts production. This includes pre-cut material inspection, in-process monitoring, and final dimensional verification. Our inspection systems are capable of capturing even minute deviations in cut paths or tolerances. Each custom laser cutting part is tracked through our workflow to ensure traceability and accountability.

9. Rapid Prototyping and Engineering Validation

We support fast development of prototypes for custom laser cutting parts, enabling clients to iterate designs and validate concepts quickly. This shortens the product development cycle and reduces the risk of late-stage failures. With rapid prototyping, clients can test multiple versions of their custom laser cutting parts before committing to full production.

10. Global Logistics and Packaging for Secure Delivery

Our custom laser cutting parts are packed and handled with care to prevent surface damage or deformation during transit. We offer customized packaging based on part geometry, quantity, and destination. Logistics partners ensure safe and timely delivery whether the parts are shipped locally or internationally. Every package of custom laser cutting parts is prepared with protective materials and labeled for traceability.