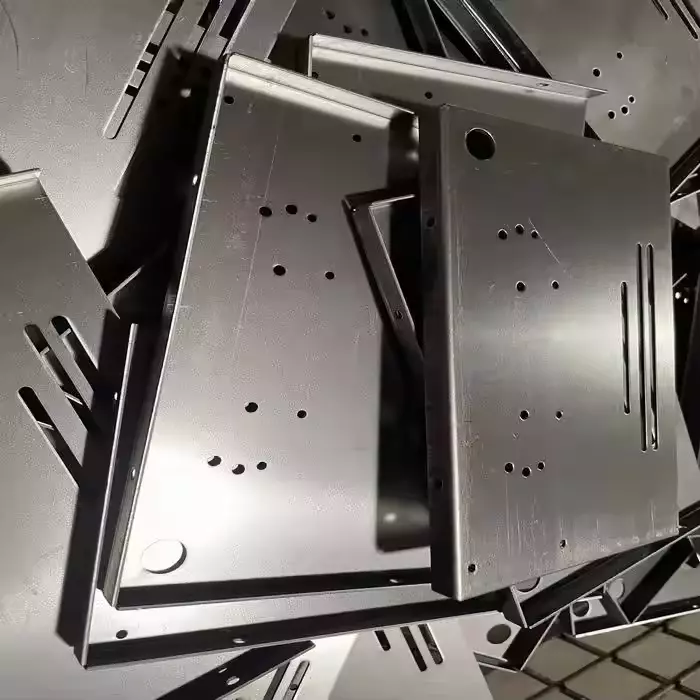

Custom Laser Cutting Metal Parts Stamping Welding Processing Stainlees Steel Aluminum Metal Hardware Parts

This custom metal fabrication service offers a comprehensive solution for producing high-quality laser cut metal parts, stamping, welding, and processing. Specializing in metal laser cutting service, the offering caters to industries such as automotive, electronics, construction, machinery, and more. By combining cutting-edge technology with skilled craftsmanship, the service provides precision parts made from stainless steel, aluminum, and other metals to meet the specific needs of each client. Whether you need complex designs, high-tolerance parts, or durable components, this service ensures that all your metal parts are crafted to perfection.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

This custom metal fabrication service offers a comprehensive solution for producing high-quality laser cut metal parts, stamping, welding, and processing. Specializing in metal laser cutting service, the offering caters to industries such as automotive, electronics, construction, machinery, and more. By combining cutting-edge technology with skilled craftsmanship, the service provides precision parts made from stainless steel, aluminum, and other metals to meet the specific needs of each client. Whether you need complex designs, high-tolerance parts, or durable components, this service ensures that all your metal parts are crafted to perfection.

1. Precision Metal Laser Cutting for Complex Designs and High Efficiency

Metal laser cutting is one of the most versatile and precise methods available for fabricating metal parts. By using advanced laser technology, we can cut intricate shapes and patterns in a wide variety of metal materials, including stainless steel and aluminum. Metal laser cutting service ensures high precision, minimal material waste, and smooth edges, which is ideal for parts that require tight tolerances and complex geometries.

This service is especially beneficial for projects that involve custom shapes or highly detailed cuts, offering superior accuracy compared to traditional cutting methods. Whether it's for prototypes, small-batch production, or large-scale manufacturing, metal laser cutting service delivers reliable and repeatable results for any application.

2. Custom Stamping and Forming for Versatile Metal Parts

Metal stamping and forming are essential processes for producing consistent, high-quality parts in large volumes. We specialize in custom metal stamping that allows for the production of complex shapes and parts from metal sheets. Stamping can be used to create a wide range of metal components, from simple brackets to intricate parts with multiple folds and bends.

This process is especially suitable for industries that require mass production of high-precision components. Stamping also helps in improving part durability and strength, which is critical for applications where the parts need to withstand high stress and harsh conditions. For metal laser cutting service, stamping can further enhance the efficiency and precision of the parts produced, making it an excellent combination for producing robust and reliable parts.

3. High-Quality Welding for Strong, Durable Assemblies

After the parts are laser cut and stamped, welding becomes the next critical step for creating durable assemblies. We offer a range of welding methods, including MIG welding, TIG welding, and spot welding, depending on the project requirements. Welding is used to join various metal parts together, ensuring a secure and robust final assembly.

For stainless steel, aluminum, and other metals, we employ precise welding techniques to ensure the parts are not only structurally strong but also retain their material properties. Welding is also essential when creating custom metal hardware parts that require a combination of different metal types. By offering a reliable metal laser cutting service, we can guarantee that welded parts meet the highest industry standards and are built to last under demanding conditions.

4. Comprehensive Processing for Customized Metal Parts

In addition to laser cutting, stamping, and welding, we also offer a wide range of additional processing options to further enhance the functionality and appearance of your metal parts. These processes include deburring, polishing, machining, and surface treatments such as anodizing, powder coating, and electroplating.

These post-processing steps help improve the parts' surface finish, increase corrosion resistance, and provide a smoother texture. For metal laser cutting service, these added processing options ensure that each metal part not only meets the functional requirements but also looks polished and professional. This is particularly important for industries where the aesthetic appeal of the parts is just as important as their functionality.

5. Tailored Solutions for a Wide Range of Applications

This custom metal fabrication service is designed to meet the specific needs of a variety of industries, offering tailored solutions for each project. Whether you're in the automotive, construction, machinery, or electronics sector, we can provide the precise parts and components required for your application. Our metal laser cutting service allows for a high level of customization, ensuring that parts are made to fit the exact specifications.

From small, custom runs of specialized parts to large-scale production runs, this service can handle any order size and complexity. The ability to work with stainless steel, aluminum, and other metals provides flexibility for a wide range of applications. Additionally, by combining metal laser cutting service with other processes like welding and stamping, we can deliver fully integrated solutions that meet both the functional and aesthetic requirements of your project.