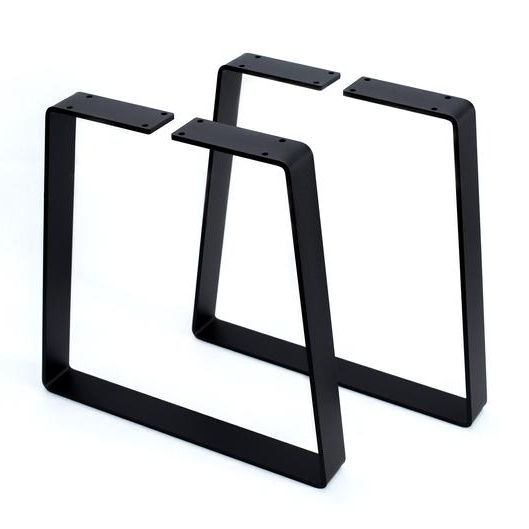

Custom Made Metal Table Leg Frame Steel Tube Processing Metal Chair Leg Frame

- Customized

- China

- in 35days

We specialize in custom made furniture leg frame, providing comprehensive , high-quality chair and table leg frame . Our expertise in creating custom solutions ensures that each chair and table leg frame is precisely manufactured to meet unique design and functional requirements. We utilize advanced metal fabrication technologies to produce durable and accurate components that serve various structural and industrial applications.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 2000 | > 2000 |

| Lead time (days) | 30 | To be negotiated |

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

Our advantage for metal fabrication a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

Usage: | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

Tolerance: | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

Finish: | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

Color: | Optional with various colors as required by customer. |

OEM: | Yes, can produce based on customer's drawings or samples. |

Lead time: | 15-20days for mold and 30days for first lot. |

Advanced Tube Bending Processing

Our steel tube rack fabrication process includes precise steel pipe bending processing, enabling us to form complex shapes and angles with consistent accuracy. This capability is essential for producing custom metal frames and tubular metal frames that fit exact specifications and assembly needs. Through CNC bending technology, we control bending radius and alignment, ensuring the integrity and strength of each steel tube frame component. The use of advanced steel pipe bending processing allows us to maintain high standards of quality and repeatability in every tubular metal frame and custom metal frame we produce.

Custom Metal Frame Design and Manufacturing

We collaborate closely with clients to develop custom metal frames tailored to their project demands. Our process integrates design considerations such as load-bearing capacity, geometry, and material selection to optimize the performance of each steel tube rack. The tubular metal frame products we fabricate are engineered for robustness, versatility, and ease of installation in diverse applications like furniture, automotive, and construction. Every custom metal frame benefits from thorough quality control and precise fabrication techniques to meet demanding specifications, ensuring each tubular metal frame maintains structural integrity.

Material Selection and Fabrication Quality

Our fabrication process employs high-grade steel tubes selected for their mechanical strength and durability. We ensure that every steel tube used in the fabrication of custom metal frames and tubular metal frames meets rigorous quality standards. The steel pipe bending processing and welding techniques we apply contribute to the overall reliability and longevity of the final steel tube rack assemblies. Our commitment to quality in material selection and processing guarantees that the custom metal frame and tubular metal frame perform reliably in their intended environment.

Welding and Assembly Precision

The assembly of steel tube frames involves skilled welding practices to join bent tubes into stable and precise structures. Our welding processes guarantee strong bonds without compromising the dimensional accuracy achieved through bending. This ensures that the custom metal frame assemblies and tubular metal frames maintain structural integrity and meet the specifications required by end-use applications. Seamless integration of welding with steel pipe bending processing enhances the durability and stability of every tubular metal frame and custom metal frame produced.

Versatile Applications of Tubular Metal Frames

The steel tube racks and tubular metal frames we fabricate are widely utilized in sectors such as industrial storage, furniture manufacturing, automotive frameworks, and architectural support structures. Our ability to deliver tailored steel tube frames and tubular metal frames allows customers to implement solutions that enhance operational efficiency and structural performance. Each custom metal frame and tubular metal frame produced supports diverse design needs and functional criteria. Tubular metal frames fabricated through our steel pipe bending processing methods offer strength and flexibility for many industrial applications.

Efficient Production and Customer Service

We maintain an efficient production workflow for steel tube rack fabrication, from material procurement through bending, welding, and final assembly. Our commitment to quality and customization ensures that clients receive products on schedule and to specification. By focusing on customer requirements and maintaining precise control over each stage of fabrication, we deliver steel tube frames and tubular metal frames that exceed expectations. Continuous improvement in steel pipe bending processing and custom metal frame assembly ensures ongoing excellence in tubular metal frame product delivery.