Professional Factory Direct Price Custom Tube Fabrication Cnc Laser Cutting Bending Welding Servide Aluminum Stainless Steel Tube Frame

We provide professional factory direct price custom tube fabrication services, specializing in CNC laser cutting, bending, and welding for aluminum and stainless steel tube frames. Our expertise lies in delivering precision-engineered tube fabrication solutions tailored to meet the demands of diverse industries. By combining advanced manufacturing technologies and skilled craftsmanship, we ensure every tube fabrication project achieves optimal quality, structural integrity, and functional performance.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling | |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

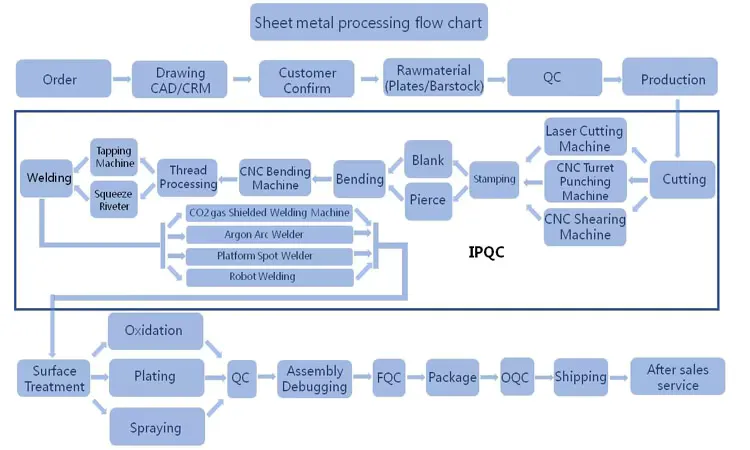

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

Advanced CNC Laser Cutting Technology

Our tube fabrication service utilizes cutting-edge CNC laser cutting technology to achieve exceptional accuracy and repeatability in cutting tube materials. The precision of CNC laser cutting allows us to produce complex shapes and detailed profiles with minimal material waste. This technology is particularly effective for aluminum and stainless steel tubes, where maintaining clean edges and dimensional accuracy is critical. The laser cutting process ensures that each tube fabrication component fits precisely within the assembly, reducing the need for secondary adjustments.

Precision Tube Bending Capabilities

We specialize in custom tube fabrication with advanced bending techniques designed to create precise bends without compromising the structural strength of the tubes. Our CNC tube bending machines are capable of producing consistent, repeatable bends for a variety of tube diameters and wall thicknesses. This capability allows us to fabricate tube frames with complex geometries required by automotive, furniture, and industrial applications. Proper tube bending in our tube fabrication process ensures the final assembly meets design specifications and performs reliably under operational stresses.

Expert Welding Services for Tube Assembly

Welding is a critical component of our tube fabrication service, enabling the assembly of individual tube pieces into robust frames and structures. We employ various welding techniques suitable for aluminum and stainless steel, such as TIG and MIG welding, to achieve strong, clean welds with excellent corrosion resistance and mechanical properties. Our professional welding process ensures that tube fabrication assemblies maintain their integrity and durability throughout their service life. Post-welding inspections confirm that each welded joint meets stringent quality standards.

Material Selection and Quality Control

Our tube fabrication process includes careful selection of aluminum and stainless steel materials to suit specific application requirements. We work with high-grade metals known for their strength, corrosion resistance, and formability. Throughout the tube fabrication workflow, we implement strict quality control measures including dimensional inspections, weld quality testing, and surface finish evaluations. These controls guarantee that every tube fabrication product leaving our facility conforms to customer specifications and industry standards.

Customization and Scalability

Our factory direct tube fabrication services offer high flexibility to accommodate custom designs, varying production volumes, and diverse industry needs. We collaborate closely with clients to understand design criteria and functional requirements, enabling us to tailor the tube fabrication process accordingly. Whether producing prototype runs or large-scale manufacturing, our adaptable production system ensures consistent quality and timely delivery of tube fabrication products. This approach supports innovation and responsiveness in product development cycles.

Post-Processing and Finishing Options

In addition to tube cutting, bending, and welding, we provide comprehensive post-processing services to enhance the appearance and performance of tube fabrication products. These services include deburring, polishing, anodizing, and powder coating, which improve corrosion resistance and aesthetic appeal. Finishing processes are selected based on material type and end-use requirements to ensure optimal product longevity. Proper post-processing completes the tube fabrication cycle, preparing components for seamless integration into final assemblies.

Application Versatility and Industry Use

Tube fabrication products manufactured through our service are widely used in automotive frames, furniture structures, architectural elements, and industrial equipment. The combination of CNC laser cutting, precision bending, and expert welding enables us to meet the complex design and performance demands across these sectors. Our tube fabrication solutions provide reliable structural support, enhanced design flexibility, and efficient production methods, making them an integral part of modern manufacturing workflows.