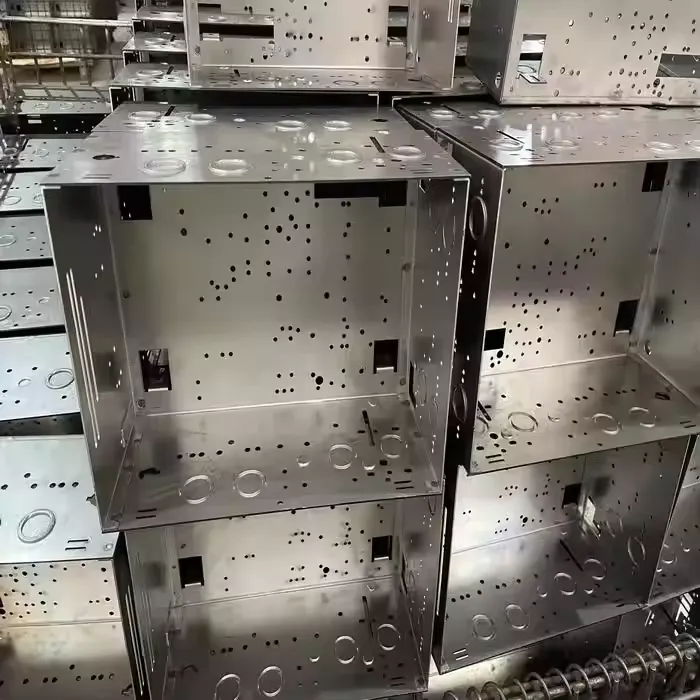

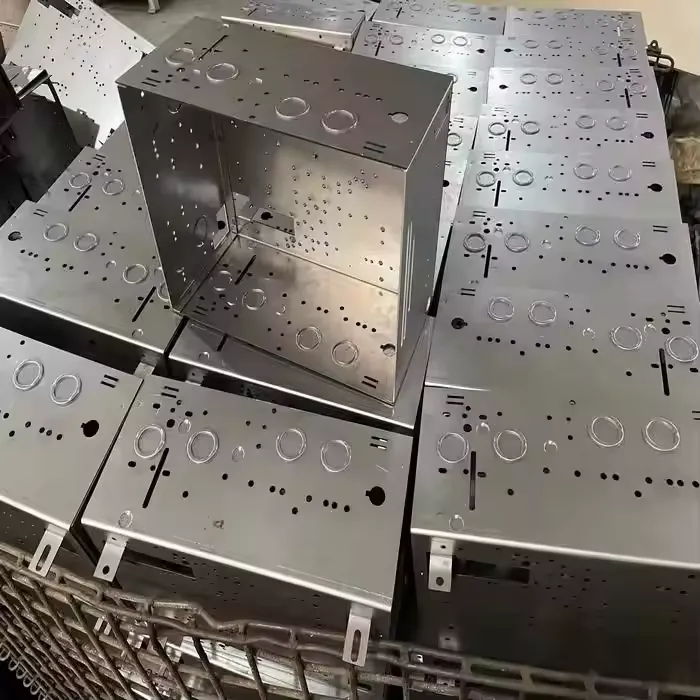

Custom Sheet Metal Cnc Laser Cut Manufacturing Service Metal Laser Cutting Welding Parts For Electrical Box

We offer custom sheet metal CNC laser cut manufacturing services, specializing in metal laser cutting and welding parts for electrical boxes. Our laser cutting manufacturing process is designed to deliver precise and efficient results, adapting to the complex requirements of electrical enclosure components.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Our advantage for metal fabrication

a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

Usage: | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

Tolerance: | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

Finish: | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

Color: | Optional with various colors as required by customer. |

OEM: | Yes, can produce based on customer's drawings or samples. |

Lead time: | 15-20days for mold and 30days for first lot. |

We specialize in custom sheet metal CNC laser cut manufacturing, focusing on producing metal laser cutting and welding parts tailored for electrical box applications. The laser cutting manufacturing process we apply emphasizes precision and adaptability to diverse design specifications common in electrical components.

By utilizing CNC laser technology, our laser cutting manufacturing achieves smooth, accurate cuts with controlled thermal effects, preserving the metal’s mechanical properties and surface quality. This precision supports the dimensional tolerances and functional requirements essential for electrical enclosures.

Different metals such as steel, aluminum, and stainless steel are processed with customized laser cutting manufacturing settings, addressing their unique characteristics. This targeted approach helps balance production efficiency and component quality effectively.

In addition to laser cutting manufacturing, we provide complementary services including welding and assembly, enabling us to deliver integrated fabrication solutions suited to electrical equipment needs. Our production scale can accommodate small prototypes as well as larger batch manufacturing.

During the entire laser cutting manufacturing cycle, we maintain close collaboration with clients to integrate feedback and ensure the finished parts meet the expected standards and project specifications.