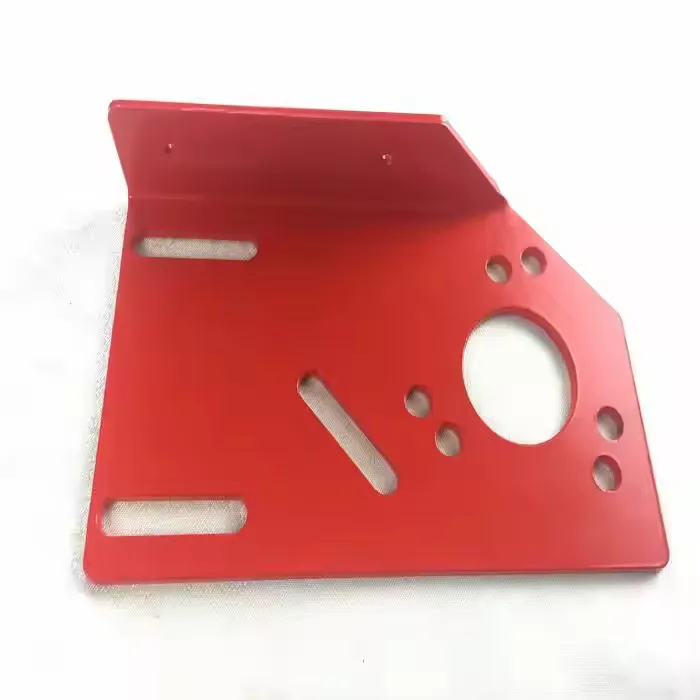

High Precision Laser Cutting Processing Service Stainless Steel Aluminum Sheet Metal Fabrication

We provide high precision laser cutting processing services specializing in stainless steel and aluminum sheet metal fabrication. Utilizing advanced laser technology, we achieve exact cuts with minimal material distortion, supporting complex geometries and fine detail that meet demanding industry standards.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

Usage: | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

Tolerance: | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

Finish: | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

Color: | Optional with various colors as required by customer. |

OEM: | Yes, can produce based on customer's drawings or samples. |

Lead time: | 15-20days for mold and 30days for first lot. |

We offer high precision laser cutting services specializing in stainless steel and aluminum sheet metal fabrication. Our advanced laser technology allows for accurate and detailed cutting, making it possible to produce complex shapes and fine details in various materials. By applying high precision laser cutting, we ensure consistent quality and reliability for all sheet metal fabrication projects.

The choice of materials, such as stainless steel and aluminum, complements the capabilities of our laser cutting process. This combination supports a clean cutting edge and minimal distortion, which is important for maintaining the integrity of each component. Our equipment is designed to handle diverse sheet metal fabrication needs while providing efficient and precise laser cutting operations.

Accuracy is a key aspect of our service. High precision laser cutting reduces the need for additional finishing steps by producing smooth edges and tight dimensional tolerances. This level of control helps in meeting stringent requirements across different industrial sectors. We implement quality checks throughout the laser cutting process to maintain consistent results in every batch.

Our high precision laser cutting solutions are suitable for multiple industries including aerospace, automotive, electronics, and medical devices. These sectors often require complex parts with exact specifications, where the precision of laser cutting becomes essential. By combining sheet metal fabrication expertise with laser cutting technology, we support both prototype development and mass production effectively.

Beyond laser cutting, we provide comprehensive sheet metal fabrication services including forming, welding, and assembly. We work closely with customers to optimize designs for laser cutting, helping to reduce material waste and improve manufacturing efficiency. Our service model accommodates a wide range of order sizes while ensuring consistent output quality throughout the production process.