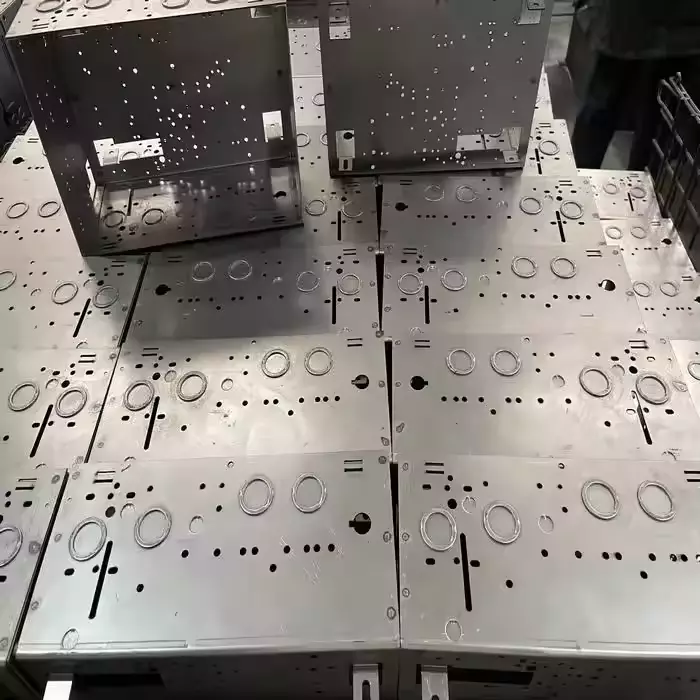

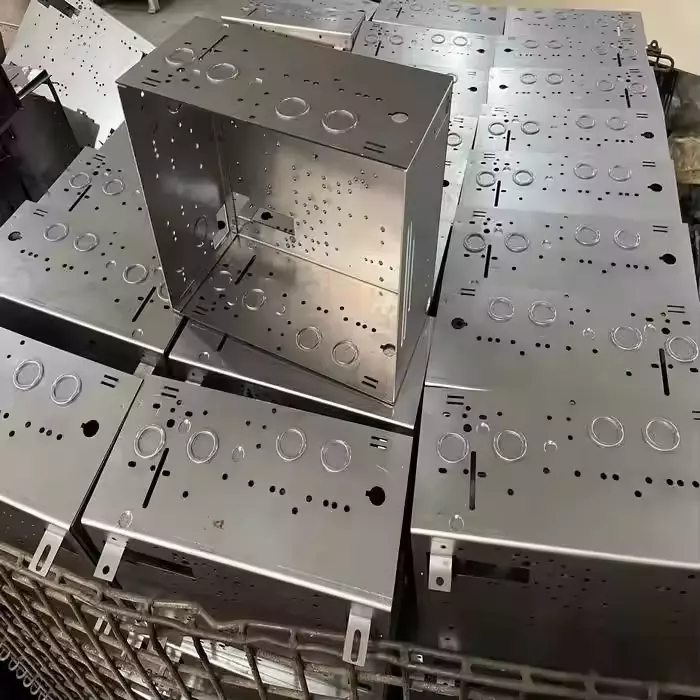

High Quality OEM & ODM Carbon Steel Sheet Metal Fabrication Custom Welding And Laser Cutting Service

This comprehensive sheet metal fabrication service for carbon steel includes a full range of services, from precision laser cutting to custom welding and assembly. Designed to meet the needs of industries such as automotive, electronics, construction, and machinery, this service offers high-quality solutions for both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) projects. With an emphasis on precision, efficiency, and cost-effectiveness, this service ensures that every project, regardless of complexity, is delivered to meet client specifications.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

This carbon steel sheet metal fabrication service offers a full range of solutions, including precision laser cutting, custom welding, and assembly. It is specifically designed for industries such as automotive, electronics, construction, and machinery, providing high-quality OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) solutions. By focusing on precision, efficiency, and cost-effectiveness, this service ensures the successful delivery of every project, no matter how complex, according to customer specifications. Particularly for stainless steel laser cutting parts, we provide the same high-level precision processing as with carbon steel to ensure quality consistency across materials.

1. Advanced Laser Cutting Technology for Precision and Efficiency

Laser cutting technology is one of the core processes in carbon steel sheet metal fabrication services. Compared to traditional cutting methods, laser cutting offers higher precision, better edge quality, and the ability to handle complex designs while minimizing material waste. This technology allows for the precise cutting of intricate shapes and patterns in carbon steel materials, ensuring that the final product meets the highest quality standards. Laser cutting is especially essential for applications that require strict tolerances and smooth cuts.

Not only is it applied to carbon steel, but stainless steel laser cutting parts also utilize this advanced technology to ensure both carbon steel and stainless steel materials meet the same precision standards. This cross-material processing capability allows clients to switch materials without compromising on quality and performance.

2. Custom Welding Services for Strong and Reliable Assemblies

After laser cutting, custom welding becomes a critical step in the production process. We offer various welding methods, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and spot welding, to meet different assembly requirements. The choice of welding technique depends on the specific needs of the project, ensuring all parts are securely connected without distortion or warping during the welding process.

Through precise heat control, the welding process ensures the structural integrity of carbon steel parts, preventing any deviations during processing. For stainless steel laser cutting parts, the same high-precision welding techniques are used to ensure strong welds and reliable final assemblies.

3. Full Customization for OEM and ODM Projects

Whether a completely new design (ODM) or a modification of existing products (OEM), we offer a high level of customization for sheet metal fabrication. By combining custom welding and laser cutting, we can precisely manufacture each part according to the specific requirements of the client, ensuring it meets both functional and quality standards.

The service supports various design formats, including CAD drawings and physical prototypes, ensuring customers receive products that align perfectly with their design and performance needs. For projects requiring stainless steel laser cutting parts, we offer the same level of customization, ensuring material conversion does not impact the final quality or performance.

4. Strict Quality Control for Consistency and Precision

We maintain strict quality control throughout the sheet metal fabrication process. Every production stage—from laser cutting to welding and assembly—undergoes comprehensive quality checks to ensure parts meet the required specifications. Each batch of products is meticulously measured for size, surface quality, and functionality, ensuring they meet the highest industry standards. For projects with high precision requirements, particularly those involving stainless steel laser cutting parts, quality control is key to ensuring the project's success.

To ensure consistency, advanced measurement equipment is used to conduct thorough checks for dimensions, flatness, and tolerance, ensuring that each part performs optimally in its intended application.

5. Surface Treatment and Post-Processing for Durability and Aesthetic Appeal

After welding, surface treatment is the final step in sheet metal fabrication. We offer various surface treatment options such as powder coating, electroplating, and anodizing, depending on customer requirements. These treatments not only enhance the appearance of the parts but also effectively prevent corrosion, wear, and other environmental factors, increasing the durability of the components.

These surface treatment processes are applicable to all types of materials, including carbon steel and stainless steel laser cutting parts, ensuring each component is not only functional but also aesthetically appealing. These post-processing measures provide additional protection for the final product and improve its service life and overall performance.