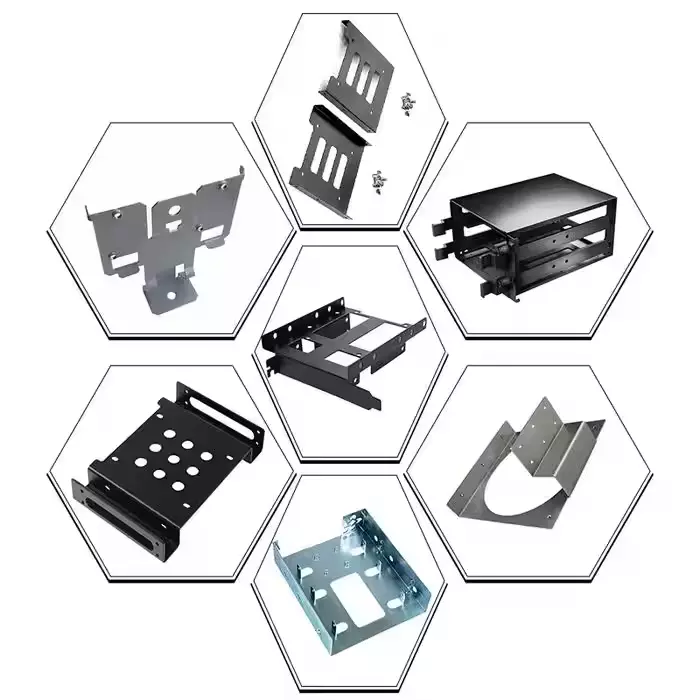

Oem Factory Metal Laser Cutting Work Custon Stainless Steel Laser Cutting Parts

We provide OEM factory metal laser cutting work specializing in custom stainless steel laser cutting parts. Our services leverage advanced laser cutting technology to deliver precision, quality, and efficiency in processing stainless steel components tailored to diverse industry requirements. The combination of cutting-edge equipment and expert craftsmanship allows us to produce laser cut stainless steel parts with exceptional accuracy and finish.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 50000 | > 50000 |

| Lead time (days) | 30 | To be negotiated |

Product Description

| Materials | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

Advanced Laser Cutting Technology

Our laser cut stainless steel parts are manufactured using high-power fiber laser cutting machines that produce clean, precise cuts with minimal heat distortion. The laser cutting process enables us to achieve intricate shapes and fine details on stainless steel sheets, which traditional methods cannot replicate easily. The precision of laser technology ensures tight tolerances, smooth edges, and consistent repeatability, making it ideal for complex design requirements. This efficiency allows us to produce laser cut stainless steel parts that meet demanding specifications reliably.

Expertise in Stainless Steel Material Handling

We focus on selecting high-quality stainless steel materials known for their superior corrosion resistance, strength, and durability. Our expertise ensures that the laser cut stainless steel parts retain their mechanical properties throughout the cutting and finishing processes. We carefully choose the appropriate stainless steel grades and thicknesses to satisfy performance and aesthetic needs. Handling stainless steel properly is crucial to achieving durable and precise laser cut stainless steel parts that last.

Customization and Design Flexibility

Our OEM factory metal laser cutting work centers on delivering fully customized laser cut stainless steel parts that precisely match client specifications. We work closely with customers to understand their design intentions and production requirements, fine-tuning laser parameters for optimal cutting speed and quality. This customization capacity allows us to fabricate laser cut stainless steel parts that fit seamlessly into larger assemblies or finished products, enhancing overall functionality.

Production Efficiency and Scalability

The laser cutting process we employ reduces material waste and shortens production cycles, supporting both small prototype batches and high-volume manufacturing runs. Our setup enables rapid job transitions, making us a dependable partner for OEM factory metal laser cutting work that can adapt to shifting client demands. This scalability ensures that laser cut stainless steel parts are delivered on time without sacrificing quality.

Post-Processing and Surface Finishing

After laser cutting, stainless steel parts often require further processing such as deburring, polishing, or surface treatments to meet application standards. We offer a range of finishing services designed to improve the corrosion resistance, surface smoothness, and appearance of laser cut stainless steel parts. These enhancements prepare the components for immediate use or integration into other products, increasing their value and durability.

Rigorous Quality Control

Throughout production, we maintain stringent quality control measures for laser cut stainless steel parts. Dimensional accuracy checks, edge quality assessments, and material verification are conducted to ensure compliance with customer requirements and industry standards. This dedication to quality guarantees reliable performance and satisfaction from the laser cut stainless steel parts we supply.