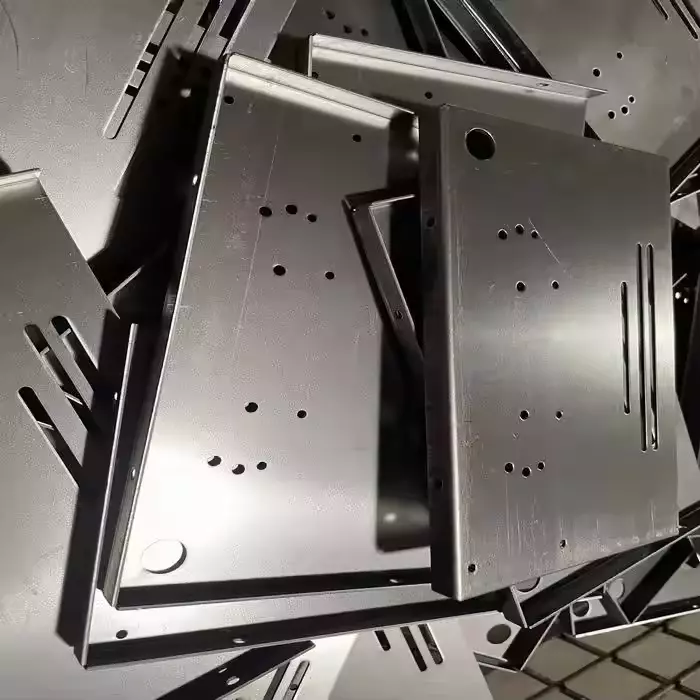

Carbon Steel Sheet Metal Laser Cutting Processing Custom Sheet Metal Enclosure Box

Custom sheet metal fabrication is an essential manufacturing process that involves the transformation of flat carbon steel sheets into customized enclosures and boxes through laser cutting and other forming techniques. This process ensures precise design adaptation for different industrial and commercial applications, emphasizing durability, performance, and reliability.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Our advantage for metal fabrication | a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Materials | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

Custom sheet metal fabrication is an essential manufacturing process that involves the transformation of flat carbon steel sheets into customized enclosures and boxes through laser cutting and other forming techniques. This process ensures precise design adaptation for different industrial and commercial applications, emphasizing durability, performance, and reliability.

1. Laser Cutting for Accuracy and Complexity

The process starts with laser cutting, which enables high-precision shaping of carbon steel materials. Laser cutting is a critical step in custom sheet metal fabrication, allowing intricate geometries and tight tolerances to be achieved efficiently. The laser technology used ensures clean edges and consistent results, essential for downstream bending and welding operations.

Laser cutting in custom sheet metal fabrication facilitates the creation of access holes, ventilation slots, and custom contours that would be difficult or inefficient to produce using other methods. It also supports batch consistency, especially important in large-scale production runs where each enclosure must conform to identical specifications.

2. Structural Benefits of Carbon Steel

Carbon steel is widely used in custom sheet metal fabrication due to its strength, formability, and cost-effectiveness. It offers reliable performance in harsh or demanding environments. Its resistance to wear and mechanical stress makes it ideal for protective enclosures that shield sensitive components from external impact.

The compatibility of carbon steel with various surface finishes further enhances its application in custom sheet metal fabrication. Whether left untreated or coated for added protection, carbon steel enclosures maintain structural integrity over time. This material supports various fabrication operations like bending, punching, welding, and cutting with minimal degradation.

3. Customization for Specific Applications

One of the core strengths of custom sheet metal fabrication is the flexibility it offers in terms of size, shape, and design. Enclosures can be fully customized to meet customer-specific requirements, accommodating different types of mounting, component layout, cable routing, and ventilation. This flexibility is especially important in sectors where equipment footprints vary and standard enclosures are inadequate.

Customers can request enclosures in a range of configurations—from wall-mounted boxes to floor-standing cabinets—tailored to match exact technical and aesthetic needs. Custom sheet metal fabrication enables seamless integration with existing infrastructure or product lines, minimizing the need for adapters or modifications.

4. Multi-Step Fabrication: Bending, Welding, and Assembly

After laser cutting, the next phases in custom sheet metal fabrication include bending, welding, and assembly. These steps shape the flat cutouts into three-dimensional enclosures and reinforce structural integrity. Bending is carried out with precision press brakes that create exact angles without cracking or weakening the material.

Welding secures joints and ensures a rigid box construction. Depending on the application, different welding techniques may be used, all of which are compatible with carbon steel. These assemblies are inspected to ensure alignment, load-bearing capacity, and sealing where necessary. This multi-step approach within custom sheet metal fabrication leads to products that are functional and visually uniform.

5. Adaptability Across Industries

Custom sheet metal fabrication is relevant across a diverse range of industries. In the electrical sector, it is used for control panels and switch boxes. In manufacturing and automation, custom enclosures are designed to house machinery controls and pneumatic systems. In transportation, fabricated metal boxes protect sensors and batteries.

This versatility extends to HVAC, data centers, medical equipment, and more. Each industry benefits from custom sheet metal fabrication due to the ability to engineer enclosures with features that align precisely with end-use conditions. These include resistance to moisture, vibration absorption, and compatibility with cooling systems.