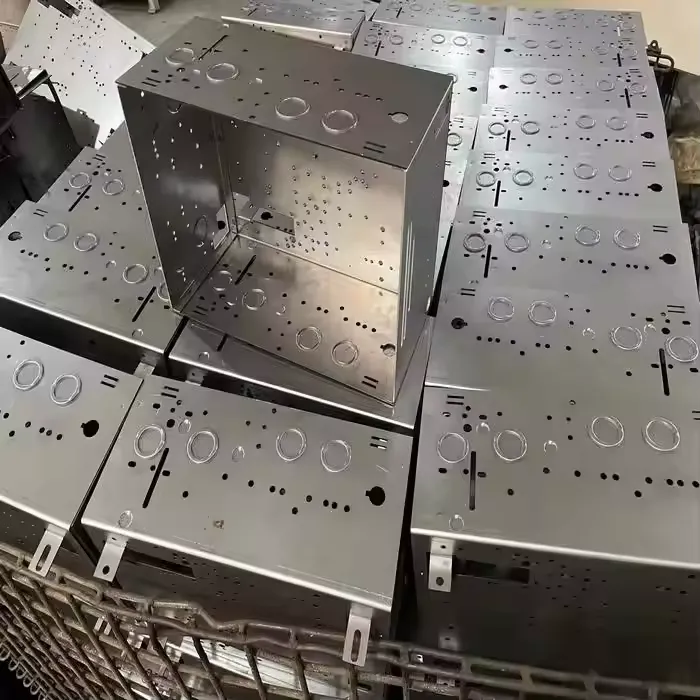

Custom Metal Case Encolsure Powder Coating Sheet Metal Box Bending Forming Sheet Metal Fabrication Service

We provide precision sheet metal fabrication services focusing on metal case and enclosure production. Our capabilities include CNC bending, forming, powder coating, and the fabrication of laser cut sheet metal parts designed for durability and functional integration across multiple applications.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Our advantage for metal fabrication

a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

Usage: | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

Tolerance: | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

Finish: | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

Color: | Optional with various colors as required by customer. |

OEM: | Yes, can produce based on customer's drawings or samples. |

Lead time: | 15-20days for mold and 30days for first lot. |

Tailored Fabrication of Powder Coated Sheet Metal Boxes and Laser Cut Enclosures

We focus on the fabrication of metal boxes and enclosures using a structured combination of cutting, shaping, and finishing processes. Our production is driven by advanced laser technology that allows us to manufacture precise and functional laser cut sheet metal parts used in different enclosures and control units.

Functional Sheet Metal Structures

By applying targeted cutting paths and engineered folding strategies, we construct metal housings that align with assembly and integration requirements. The integration of laser cut sheet metal parts helps achieve consistent cutouts, ventilation layouts, and fastening zones in every design.

Clean Cutting and Smooth Edges

Our facilities utilize high-performance laser systems that allow us to define detailed outlines in steel, stainless steel, and aluminum. Each of the laser cut sheet metal parts we produce is clean-edged, helping reduce post-processing work and enhancing structural matching accuracy.

Powder Coating on Assembled Surfaces

We apply powder coatings to enclosures post-fabrication for enhanced protection and surface finish. The coating is uniform even on the edges of laser cut sheet metal parts, giving a consistent appearance while protecting the box or case from wear or corrosion.

Enclosure Fabrication from the Ground Up

From raw sheet to finished form, we bend, weld, and coat components into robust structures. Our experience in handling laser cut sheet metal parts allows us to deliver assemblies ready for hardware installation or cable routing without additional modification.

Application in Equipment and Control Systems

We create custom enclosures for industrial machines, electronic controls, and automation cabinets. The accuracy of laser cut sheet metal parts supports tight assembly tolerances and secure fitment in both standalone and integrated systems.

Materials That Adapt to Demand

We fabricate in stainless steel, mild steel, and aluminum, depending on required weight, rigidity, or corrosion resistance. All materials are compatible with our processes for producing laser cut sheet metal parts, ensuring structural integrity and aesthetic consistency.

High Repeatability in Series Production

We support both small-batch prototyping and scaled manufacturing. Once designs are validated, our processes allow rapid and repeated production of laser cut sheet metal parts for large-volume enclosures with little variation between units.

Technical Input and Layout Planning

We assist clients in refining box layouts, optimizing cutouts, and adapting structures to technical needs. This makes each design more efficient and ensures the laser cut sheet metal parts function optimally in final use scenarios.

Flexible Assembly Options

We offer fastener insertion, hinged access points, and removable panels, using modular construction principles. The consistent precision of our laser cut sheet metal parts ensures these assemblies remain interchangeable and stable in demanding conditions.