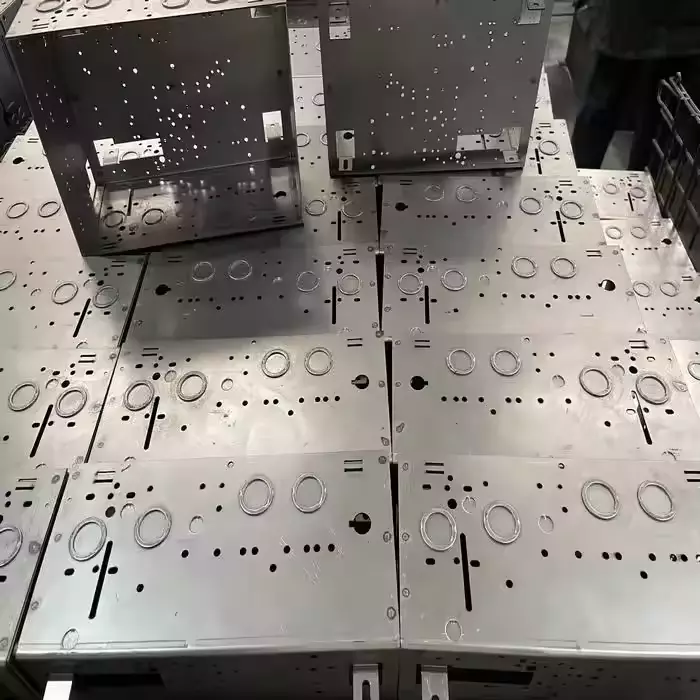

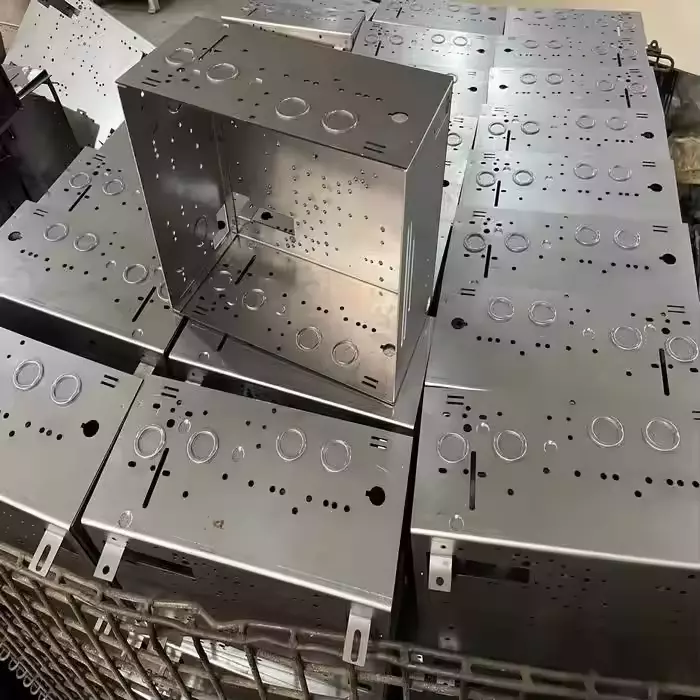

Custom Laser Cutting Processing Steel Sheet Metal Forming Metal Sheet Electricial Enclosure Box

- Customized

- China

- in 35days

We provide professional custom laser cutting processing services specializing in steel sheet metal forming, with extensive experience in manufacturing high-quality sheet metal fabrication box products. Our comprehensive process covers everything from precise laser cutting to accurate forming, ensuring every sheet metal fabrication box meets stringent customer requirements.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Precision Laser Cutting Technology

Laser cutting is a critical step in producing a sheet metal fabrication box. We utilize advanced laser equipment capable of delivering high-precision cuts with smooth edges and no burrs. This technology allows us to cut complex shapes flexibly, fulfilling diverse design demands while ensuring the structural integrity and ease of assembly of each sheet metal fabrication box.

Steel Sheet Forming Expertise

Forming is the core stage in manufacturing a sheet metal fabrication box. We apply various metal forming techniques, including bending, stamping, and stretching, to shape laser-cut steel sheets into box structures that comply with design specifications. Our efficient forming process guarantees the mechanical strength and dimensional stability required for sheet metal fabrication box products to endure challenging operating conditions.

Functional Design for Electrical Enclosures

Focusing on the electrical applications of sheet metal fabrication box products, we prioritize protective features, thermal management, and installation convenience. The enclosure design effectively shields internal electrical components from external impacts and environmental hazards. Additionally, ventilation and heat dissipation are optimized within the sheet metal fabrication box to ensure stable and safe operation of electrical equipment.

Surface Treatment and Corrosion Resistance

After forming, our sheet metal fabrication box products undergo various surface treatments such as powder coating, electrophoresis, and galvanization. These treatments significantly enhance corrosion resistance and aesthetic appeal, prolonging product lifespan. Thoughtful surface processing enables the sheet metal fabrication box to withstand harsh environments while maintaining consistent performance over time.

Rigorous Quality Control System

A comprehensive quality management system governs every production phase of the sheet metal fabrication box. Dimensional inspections during laser cutting, tolerance control throughout forming, and corrosion resistance testing after surface treatment ensure compliance with design and performance standards. Continuous monitoring and improvement processes guarantee reliable and stable product quality for our customers.

Custom Solutions and Industry Applications

We offer fully customized sheet metal fabrication box solutions tailored to client requirements. Whether producing small batches or large-scale orders, we ensure timely delivery without compromising quality. Our products serve diverse sectors including electrical equipment, machinery manufacturing, telecommunications, and industrial automation, helping clients protect their devices and optimize layouts effectively.