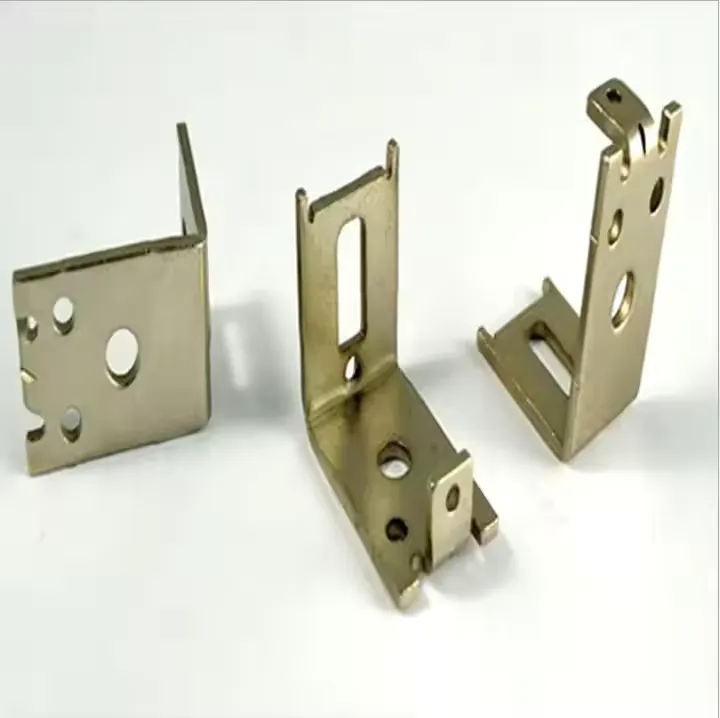

Oem Factory High Precision Sheet Metal Stamping And Fabrication Servcie

We provide OEM factory-level metal stamping and fabrication solutions, combining precision manufacturing with adaptable production capabilities. Our expertise covers sheet metal processing, advanced tooling, structural stamping, and component-level fabrication, supporting a wide range of industrial requirements.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Materials: | 1) AL1060, AL6061, AL6061, AL5052 etc. |

Specification | 1) According to customers' drawings |

Usage: | Agriculture Machinery, Farms, Furniture, Power, Appliance, Auto, Building, Solar Energy, Instrumentation, Medical device. |

Mold Material | Cr12 |

Mfg Process: | Mold Make,Laser Cutting, bending, stamping/punching, welding,Assembly ,Packing. |

Finish: | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

Drawing format | DWG, DXF, Stp, Igs, PDF, Jpg, etc. |

Service Type | OEM&ODM |

Comprehensive Metal Stamping and Fabrication Solutions

We specialize in delivering metal stamping and fabrication services that accommodate various forms, functions, and performance demands. From brackets and plates to complex structural components, our production process transforms raw sheet metal into reliable industrial parts.

Fine-Detail Sheet Stamping

Our sheet metal stamping process enables us to create intricate shapes with consistent precision. These metal stamping and fabrication techniques are essential for producing components that require exact cutouts, bend lines, and fastening zones.

Advanced Tooling Integration

We utilize progressive dies and compound tooling to streamline operations and improve part accuracy. By integrating such tooling into our metal stamping and fabrication workflow, we reduce cycle times and improve dimensional uniformity.

Controlled Metal Fabrication Procedures

Beyond stamping, we conduct a full range of fabrication tasks including shearing, bending, hole punching, and trimming. Our metal stamping and fabrication services allow for seamless production transitions, ensuring a high-quality output across multiple formats and part geometries.

High Strength Material Processing

We work with stainless steel, carbon steel, and aluminum materials to meet different strength and corrosion resistance demands. These materials are carefully selected and processed during our metal stamping and fabrication cycles to meet the load and environmental performance needed.

Durable Assembly Options

We offer welding, riveting, and fastening for finished assemblies. These post-fabrication options are part of our broader metal stamping and fabrication services and help clients receive parts that are closer to final application.

Finishing Techniques for Functionality

Surface options such as galvanizing, anodizing, and powder coating are available upon request. These treatments enhance part durability, wear resistance, and visual consistency, and are integrated smoothly into our metal stamping and fabrication workflow.