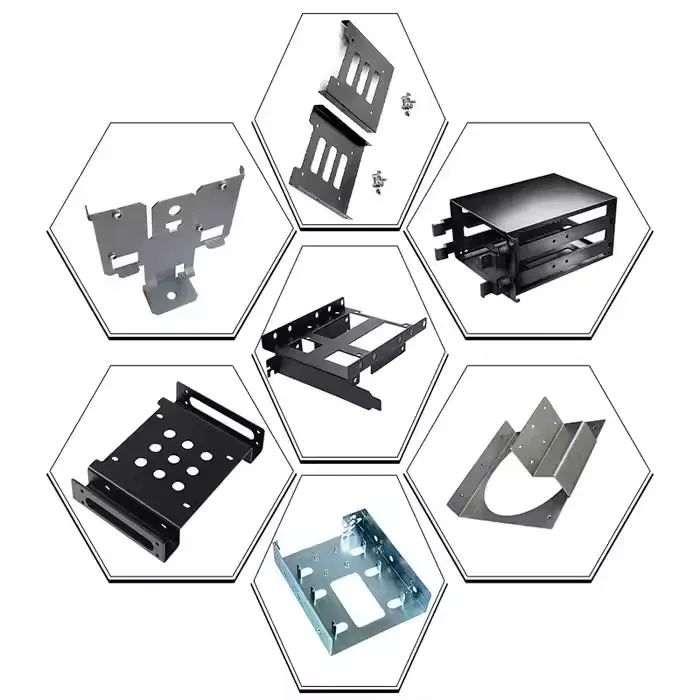

High Precision OEM Manufacturing Stainless Steel Aluminum Sheet Bending Laser Cutting Welding Service Sheet Metal Fabrication

We provide comprehensive metal fabrication services with a focus on stainless steel and aluminum sheet processing. Our capabilities include precise bending, laser cutting, and welding, tailored to complex structural designs and customized product requirements across a wide range of industries.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 50000 | > 50000 |

| Lead time (days) | 30 | To be negotiated |

Our advantage for metal fabrication

a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

Materials: | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

Usage: | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

Molds: | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

Mfg Process: | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

Tolerance: | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

Finish: | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

Color: | Optional with various colors as required by customer. |

OEM: | Yes, can produce based on customer's drawings or samples. |

Lead time: | 15-20days for mold and 30days for first lot. |

Full-Service Sheet Metal Processing

Our metal fabrication services are tailored to meet diverse structural and functional needs. Whether producing lightweight aluminum components or robust stainless steel frameworks, we ensure each piece aligns with the design specifications of industrial machinery and mechanical systems.

High-Accuracy Laser Cutting and CNC Bending

By integrating CNC laser cutting into our metal fabrication services, we achieve fine detailing and sharp tolerances on sheet metals. Coupled with controlled bending operations, we deliver precise geometry across a broad range of parts — from brackets to enclosure panels.

Versatile Welding Solutions

We implement welding techniques that meet complex assembly needs. Depending on the material and function, our team applies spot, MIG, or TIG welding to achieve clean seams and reliable bonding. These metal fabrication services enhance structural consistency and mechanical strength.

Multi-Material Compatibility

We process various grades of stainless steel and aluminum to support application-specific requirements such as corrosion resistance, load-bearing strength, or thermal stability. Our metal fabrication services provide solutions for parts used in harsh environments or exposed machinery.

Industrial-Grade Fabricated Components

We supply a wide variety of fabricated products, including support frames, housing units, control boxes, and enclosure shells. Each component produced through our metal fabrication services is engineered to match mechanical standards, ensuring operational compatibility and performance.

Scalable Production and Custom Assemblies

From prototyping to high-volume manufacturing, our services support flexible order sizes. Our facility can also deliver fully assembled metal structures, reducing client lead times and simplifying integration into existing product lines.

Protective and Functional Finishes

We enhance the utility and lifespan of fabricated components with various surface treatments. Options such as anodizing, powder coating, or plating are applied based on the operational context, contributing to the effectiveness of our metal fabrication services in demanding industries.

Application Across Industries

Our metal fabrication services are utilized in the construction, automotive, power systems, electronics, and agricultural sectors. We assist clients in developing customized parts suited to their equipment, infrastructure, or project needs, adapting our production to their functional priorities.

Collaborative Development

We work closely with our clients to refine design blueprints, optimize material usage, and improve manufacturability. This integrated approach ensures our metal fabrication services not only meet performance targets but also help manage cost-efficiency and lead times.