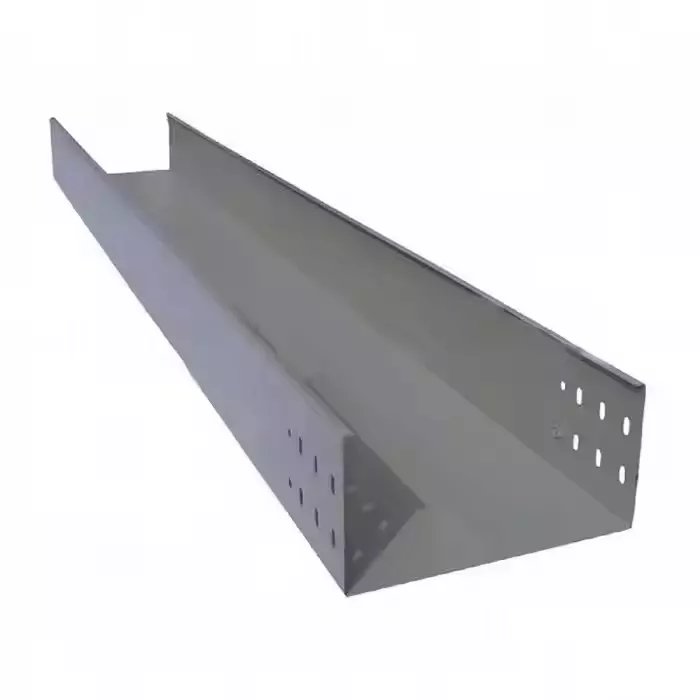

China Factory Oem Sheet Metal Fabrication Service Custom Steel Automotive Stamping Parts

We provide professional China factory OEM sheet metal fabrication service, specializing in custom steel automotive stamping parts. Our expertise focuses on delivering high-quality sheet metal fabrication custom solutions tailored to meet the rigorous demands of the automotive industry. With advanced technology and precise manufacturing processes, we ensure that each component achieves the required performance and durability standards.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Features

| Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. | |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

Precision Manufacturing Technology

Our sheet metal fabrication custom services utilize state-of-the-art stamping and forming equipment designed to produce intricate automotive parts with high precision. This technology enables us to meet strict dimensional tolerances and complex geometries necessary for automotive steel stamping parts. The accuracy of our processes reduces material waste and optimizes assembly compatibility for end-use applications.

Material Selection and Durability

We carefully select steel materials that offer excellent strength, flexibility, and corrosion resistance, essential for automotive stamping parts exposed to challenging environments. Our sheet metal fabrication custom process ensures that the chosen materials maintain their structural integrity during stamping, bending, and welding operations, contributing to the overall longevity and safety of the automotive components.

Customization and Design Flexibility

Our factory OEM sheet metal fabrication service emphasizes customization to accommodate diverse automotive design requirements. We work closely with clients to develop sheet metal fabrication custom parts that fit perfectly within vehicle assemblies. The flexibility in tooling and production allows us to handle various batch sizes, from prototypes to large-scale manufacturing, while maintaining consistent quality.

Surface Treatment and Finishing

Post-fabrication, we provide multiple surface treatment options such as powder coating, galvanizing, and electroplating. These finishes enhance corrosion resistance and aesthetic appeal, ensuring the custom steel automotive stamping parts withstand harsh environmental conditions and maintain their appearance over time. Our surface treatment processes align with automotive industry standards to guarantee optimal performance.

Quality Control and Assurance

Quality assurance is integrated throughout our sheet metal fabrication custom process. We perform rigorous inspections including dimensional verification, mechanical testing, and surface quality assessment to ensure each automotive stamping part meets required specifications. Our quality control measures prevent defects and ensure reliable performance, which is critical in automotive applications where safety and precision are paramount.

Industry Applications and Support

Our custom steel automotive stamping parts manufactured through sheet metal fabrication custom services are widely used in various vehicle systems including chassis, body panels, and structural supports. We support automotive manufacturers by providing components that enhance vehicle durability, safety, and functionality. Our commitment to precision and reliability helps our clients maintain competitive advantages in their markets.