China Metal Fabrication Manufacturer Laser Cut Bending Welding Processing Custom Stainless Steel Frame For Industry

We offer comprehensive sheet metal fabrication for industrial applications, focusing on stainless steel frame manufacturing through laser cutting, precision bending, and welding integration. Our services are designed to meet structural and functional requirements across multiple industrial sectors such as manufacturing systems, automation, heavy machinery, energy infrastructure, and equipment housing.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

1. Structural Design for Industrial Strength

We engineer stainless steel frames to support high loads, resist deformation, and maintain alignment under intensive usage conditions. Every aspect of our sheet metal fabrication for industrial applications emphasizes durability, whether it's for supporting conveyor units, electrical enclosures, or processing equipment. We rely on advanced 3D modeling and production data to guide the forming and joining of each frame.

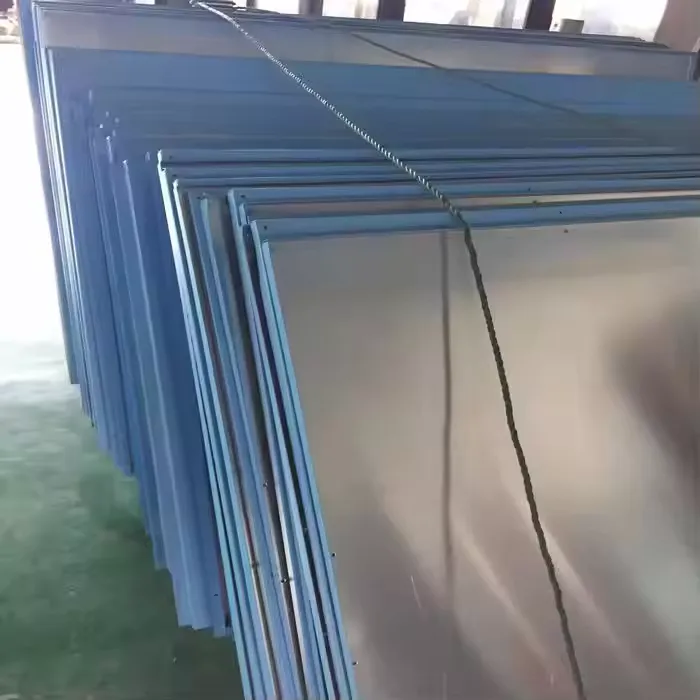

2. Precision Laser Cutting for Complex Profiles

Laser cutting is an essential process in our sheet metal fabrication for industrial applications, enabling the creation of precise cutouts, mounting slots, vent patterns, and customized geometries. Stainless steel sheets are processed with minimal thermal distortion and excellent edge quality, ensuring compatibility with industrial modules and component assemblies.

3. Bending and Reinforcement for Frame Consistency

We use CNC press brakes and automated setups to bend stainless steel with precise angles, radii, and dimensions. This enhances the consistency and strength of the frames across different assembly stages. In our sheet metal fabrication for industrial applications, every bend is engineered for structural integrity, which is critical in high-vibration, high-load environments.

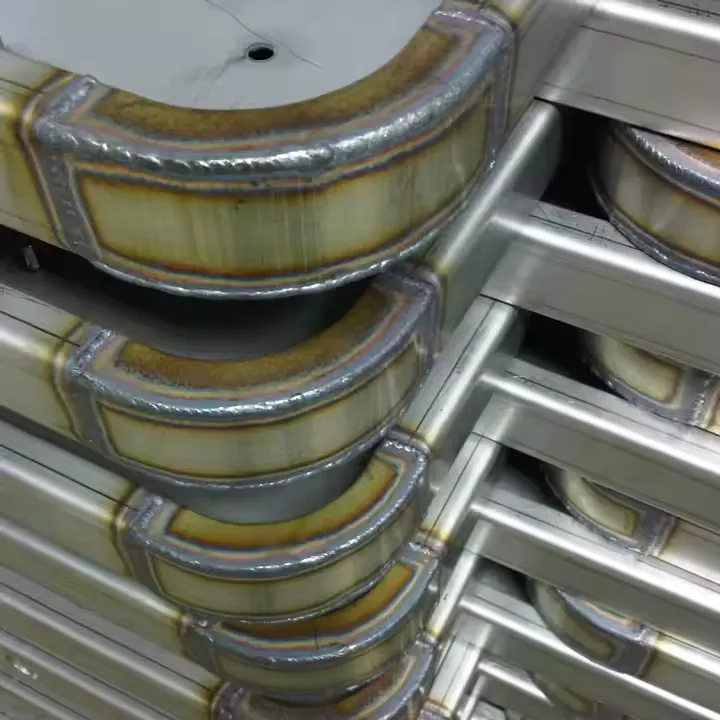

4. Welding Capabilities for Industrial Integration

Welding plays a pivotal role in sheet metal fabrication for industrial applications, particularly for joining subframe structures, brackets, and interface plates. Our MIG and TIG processes ensure full penetration and strong fusion lines, minimizing stress points while accommodating various frame geometries. Welds are refined for both strength and seamless integration with adjacent components.