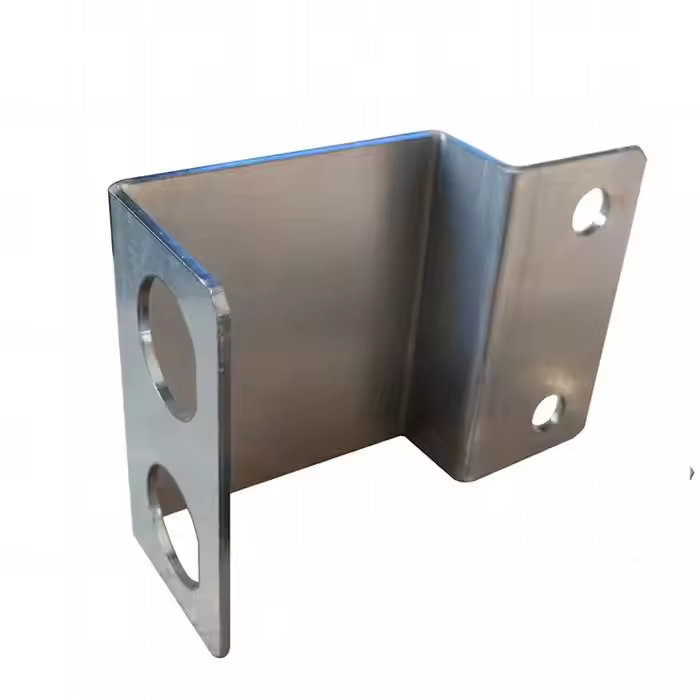

Custom Metal Works Laser Cutting Service Sheet Metal Fabrication Agricultural Machinery Parts

We specialize in custom metal works, offering laser cutting service combined with sheet metal fabricating for agricultural machinery parts. Our expertise as a sheet metal fabricator allows us to produce precise and durable components tailored to the demanding conditions of agricultural equipment. We apply advanced laser cutting techniques to enhance the accuracy and quality of each fabricated part.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

Surface treatment for different material parts:

| Aluminum Parts | Anodized, Sandblast Anodized, Polishing, Brushing, Chroming, E-coating |

| Metal Parts | Zinc plating, Nickel plating, Chrome plating, Oxide black,Powder Coated, E-coating |

| Stainless Steel Parts | Polishing, Passivating, Sandblasting, Laser engraving,lectrophoresis black, Oxide black. |

| Brass Parts | Zinc plating, Nickel plating, Chrome plating, Oxide black, Heat treatment,Powder Coated |

Precision Laser Cutting Technology

Utilizing cutting-edge laser cutting techniques, our sheet metal fabricating ensures components with smooth edges and detailed contours. This method significantly reduces material wastage while enhancing the production of complex geometries required for agricultural machinery.

Robust Material Selection

In our sheet metal fabricating process, we emphasize using materials designed to resist the environmental stresses common in agriculture. This includes various steels and metal alloys chosen for their durability and resistance to corrosion, which guarantees extended service life.

Integrated Fabrication Services

Our sheet metal fabricating encompasses multiple processes including cutting, bending, stamping, welding, and assembling. This integrated workflow enables us to deliver customized parts that conform precisely to design requirements while maintaining structural robustness.

Tailored Solutions and Accuracy

We work closely with clients to develop parts customized to their exact needs. Our sheet metal fabricating services adhere to strict dimensional tolerances, essential for components that must seamlessly integrate within agricultural equipment assemblies.

Wide Application Range

The sheet metal parts we produce serve numerous applications within the agricultural machinery field, supporting equipment functionality and operational reliability. Our manufacturing approach ensures every piece contributes positively to machine performance.