Custom Professional Sheet Metal Fabricating Small To Large Heavy Metal Fabrication Welding Assembly

We specialize in delivering flexible and high-quality stainless steel sheet metal fabrication services tailored to small, medium, and large-scale industrial requirements. Our capabilities cover a complete range of fabrication and assembly processes, ensuring precision and structural integrity in each component.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Materials | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

Flexible Stainless Steel Fabrication Solutions

Our stainless steel sheet metal fabrication services cater to multiple industries, offering tailored solutions for different sizes and complexities. By leveraging advanced cutting, bending, and welding techniques, we ensure that every component meets exact specifications and performance expectations.

Precision Cutting and Forming Techniques

Utilizing CNC laser cutting and automated bending systems, we maintain high dimensional accuracy throughout the fabrication process. This approach allows us to produce consistent stainless steel parts that integrate seamlessly into larger assemblies or standalone products.

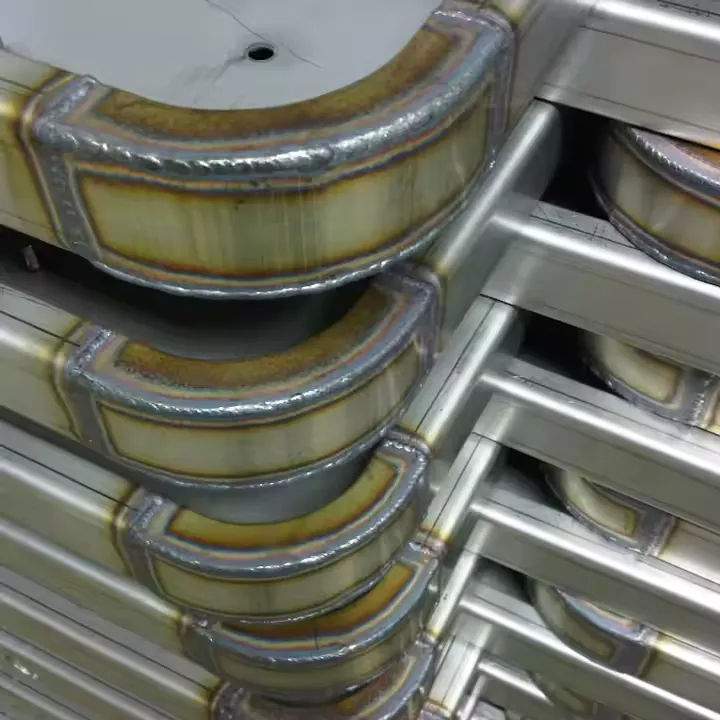

Advanced Welding and Assembly Capabilities

Our welding services support a variety of stainless steel fabrication projects, combining TIG and MIG methods to achieve strong, clean welds. We manage complete assemblies, guaranteeing structural integrity and alignment for functional end-use.

Industry Applications and Versatility

These stainless steel sheet metal fabrication services are well-suited for applications in automotive, electrical enclosures, agricultural machinery, and custom industrial equipment. We adapt to specific design requirements, ensuring compatibility and durability.

Custom Finishing and Additional Processing

Beyond primary fabrication, we offer surface treatments such as polishing and coating to enhance both appearance and corrosion resistance. Additional processes like hole drilling, threading, and fixture installation can be integrated to meet project needs.

Scalable Production and Quality Assurance

From prototype to mass production, our stainless steel sheet metal fabrication services provide flexible manufacturing solutions. We emphasize process control and inspection throughout to deliver reliable results while optimizing lead times and costs.

Collaboration and Technical Support

We engage closely with clients during design and development stages to optimize manufacturability and minimize costs. Our technical team supports custom solutions and continuous improvements in stainless steel sheet metal fabrication services.