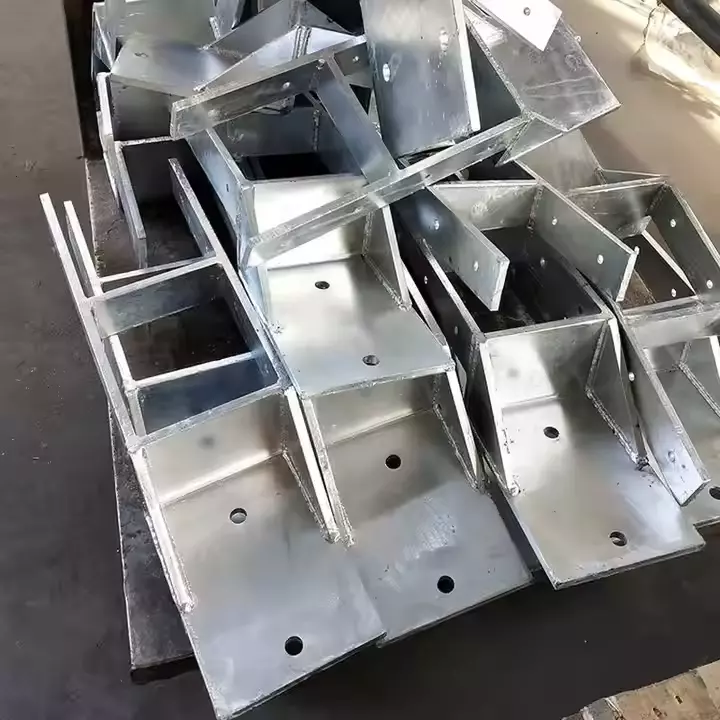

Custom Sheet Metal Fabrication Laser Cutting Bending Welding Assembly Processing Sheet Metal Assembly Parts

Custom sheet metal fabrication plays a pivotal role in modern manufacturing. When dealing with intricate product assemblies, precise cutting, bending, and welding techniques are essential for performance and efficiency. The integration of welding assembly parts has become a standard for ensuring durability and structural integrity across various industrial applications. In this context, a reliable sheet metal fabrication service provides a complete production cycle that merges accuracy with flexibility.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Products Description

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

| Our advantage for metal fabrication | a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Materials | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

Custom sheet metal fabrication plays a pivotal role in modern manufacturing. When dealing with intricate product assemblies, precise cutting, bending, and welding techniques are essential for performance and efficiency. The integration of welding assembly parts has become a standard for ensuring durability and structural integrity across various industrial applications. In this context, a reliable sheet metal fabrication service provides a complete production cycle that merges accuracy with flexibility.

1. Integrated Fabrication and Welding Capabilities

The modern approach to sheet metal fabrication is not just about forming metal—it’s about integrating different techniques seamlessly. The use of welding assembly parts allows for the permanent joining of components, delivering enhanced mechanical strength and long-term reliability. Whether used in mechanical housings, structural brackets, or custom enclosures, the accuracy of laser cutting and the precision of robotic welding significantly reduce deformation and misalignment.

Throughout the fabrication workflow, welding assembly parts serve as a key structural solution, especially for large assemblies that must endure heavy mechanical loads. These components can be formed and joined through various welding methods, supporting a range of materials including carbon steel, aluminum, and stainless steel. As a result, each part aligns precisely with the engineering intent of the design.

2. Flexibility in Complex Geometries

One of the advantages of customized sheet metal fabrication is its adaptability to complex and non-standard geometries. This flexibility is particularly critical when working with welding assembly parts, where joint configuration and part tolerance must be harmonized for secure and consistent weld seams. Every cut, bend, and weld is controlled through advanced software and CNC technology to eliminate manual deviation.

When fabricating welding assembly parts, special attention is paid to edge preparation, which ensures optimal fusion during welding. This preparation stage is vital for consistent performance, especially when the assemblies are exposed to variable stress environments such as vibration or repeated mechanical force. The ability to fabricate according to detailed design plans ensures that assembly parts will align and connect precisely as required.

The variety of welding styles compatible with welding assembly parts, such as MIG, TIG, and spot welding, gives engineers wide latitude in selecting the best combination of strength, aesthetics, and cost.

3. Design-to-Manufacture Integration

Modern fabrication services increasingly involve customers in the early stages of design. For welding assembly parts, this collaborative process ensures that product geometry is optimized not only for function but also for manufacturability. Considerations such as bend radius, hole alignment, and weld access are integrated into the early design stages to prevent rework and improve production flow.

By considering welding needs at the design phase, manufacturers minimize bottlenecks during production. For instance, pre-cut holes, slots, or notches that align with welding assembly parts allow for faster assembly with lower error rates. These strategic enhancements contribute to time and cost savings, especially when production is scaled.

In many cases, prototypes are developed using rapid fabrication techniques. These functional samples include real welding assembly parts, which allows for early-stage testing and iterative adjustments before full-scale production.

4. Application-Specific Structural Assembly

The performance of sheet metal products depends heavily on the quality of the welded connections. Therefore, welding assembly parts are used to deliver purpose-specific mechanical properties tailored to various applications, including electrical cabinets, machinery frames, HVAC components, and vehicle panels. These assemblies are not generic but are engineered for the operating environment they serve.

For example, in HVAC or ventilation systems, lightweight yet sturdy assemblies are required to maintain form over time and resist corrosion. In such applications, welding assembly parts are often combined with powder-coated finishes or surface treatments that further enhance durability. In industrial machinery, weld joints must withstand continuous vibration, requiring not only proper material selection but precise weld execution.

By fabricating these parts with consistent process controls, manufacturers ensure that the end-use product meets both physical and functional performance targets without compromise.

5. Efficient Workflow and Quality Assurance

Efficiency in fabrication depends on an uninterrupted production flow, especially when integrating welding assembly parts into a larger process. Automation, real-time quality monitoring, and lean production techniques are crucial in reducing cycle time and ensuring repeatability. Every piece that includes welding assembly parts is evaluated during and after assembly to detect warping, misalignment, or incomplete fusion.

In many fabrication environments, traceability is implemented at each stage, allowing for detailed feedback and documentation of the weld processes. Visual inspections, destructive and non-destructive testing (NDT), and final fit checks are standard practices for high-value assemblies.

Manufacturers can provide packaging and labeling tailored for ready-to-assemble welding assembly parts, allowing for easy tracking and downstream integration. This reduces the handling burden for OEMs and enables faster deployment at the final assembly stage.

The continuous improvement in automation and control systems ensures that even the most complex sheet metal products—particularly those involving intricate welding assembly parts—are produced efficiently, with tight tolerances and superior quality.