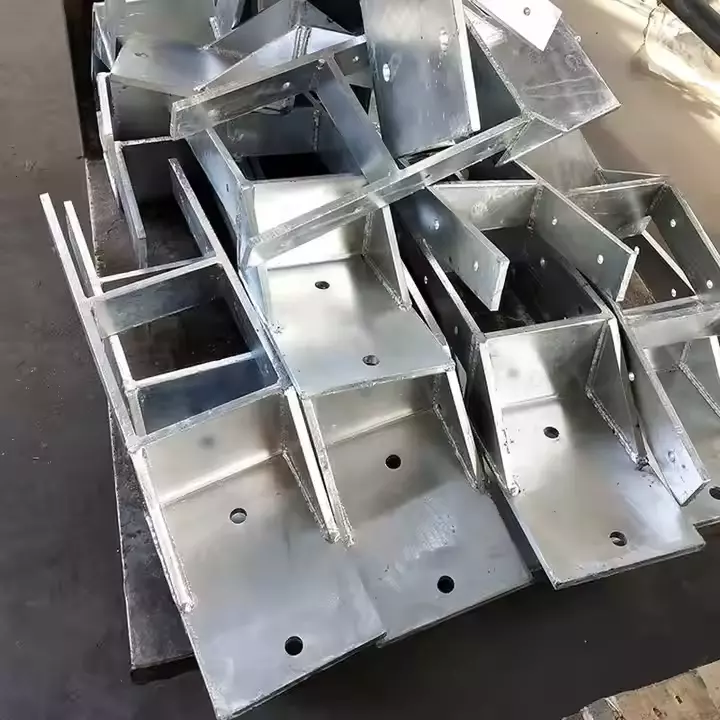

China Factory Welding Fabrication Service Stainless Steel Aluminum Sheet Metal Frame Assembly Parts

We offer welding fabrication services focused on stainless steel and aluminum sheet metal frame assembly components. Our manufacturing facility delivers structural and functional sheet metal solutions through a tailored Custom welding assembly approach. From individual brackets to full metal frames, our capabilities cover every step from cutting and forming to precise multi-point welding and frame assembly integration. Each assembly project follows a controlled and repeatable workflow to ensure accurate alignment, solid joints, and reliable structural performance.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

1. Comprehensive Material Processing

We work with stainless steel and aluminum in various forms to accommodate complex design requirements. Our Custom welding assembly begins with careful selection and preparation of sheet metal, which ensures compatibility with our welding techniques and minimizes distortion. Stainless steel parts undergo edge cleaning and oxide removal before welding to achieve solid joints and aesthetic surfaces. For aluminum components, we manage oxidation and thermal behavior with precision surface treatment and accurate preheating strategies. Our experience with mixed-metal assemblies allows for seamless integration between different materials in a single Custom welding assembly.

Each component is cut and formed to tight tolerances prior to welding. This ensures consistent fitment across welded frames and prevents post-weld correction steps. We optimize grain orientation, stress distribution, and structural layout during the preparation phase to create assemblies with enhanced mechanical performance. Whether forming structural brackets or complex enclosures, our Custom welding assembly process accommodates both large and compact formats while maintaining uniformity.

2. Precision Welding Technology

We use advanced welding methods such as MIG, TIG, spot, and pulse welding depending on the material, thickness, and assembly configuration. Stainless steel assemblies often rely on MIG welding to ensure strength and speed. TIG welding is preferred for aluminum parts where weld clarity and control are critical. For repetitive sheet connections in frame structures, we apply spot welding with consistent pressure and minimal heat distortion. Our Custom welding assembly process includes automation options for high-volume consistency and robotic welding paths for geometrically complex components.

Our in-house jigs and fixtures allow for accurate alignment of parts during welding. This eliminates deviation and ensures joint symmetry across multiple units. Weld sequencing and thermal management are designed to prevent residual stress and maintain the flatness and straightness of the welded frames. Each Custom welding assembly is carefully monitored by trained professionals to maintain weld penetration, bead profile, and minimal spatter generation. Heat-affected zones are minimized to preserve the mechanical properties of the base materials.

3. Frame Assembly and Multi-Part Integration

We specialize in assembling full sheet metal frames from individually fabricated parts. These welded structures are used in control boxes, display frames, support systems, and machinery enclosures. Our Custom welding assembly process ensures tight fitment, clean junctions, and structural balance. Each part is designed with interlocking features, tabs, or guide slots that simplify alignment during welding and contribute to overall accuracy.

Our assembly operations include both manual and semi-automated systems depending on complexity. Frames are tacked, welded, and post-checked for flatness, squareness, and weld conformity. In modular frame assemblies, individual welded units are combined using precision alignment tools to achieve large-scale integration. We also manufacture hybrid frames using both aluminum and stainless steel, managing joint differences with filler selection and weld control. Each Custom welding assembly is tailored to its functional load, thermal exposure, and environmental condition.

Surface finishing is optional and applied according to downstream requirements. We prepare surfaces for painting, powder coating, or anodizing depending on material type and customer needs. All assemblies are deburred and cleaned before packaging to ensure readiness for integration into final products.

4. Quality Control and Welding Inspection

Our quality management system applies thorough inspection methods to all Custom welding assembly projects. Every welded structure undergoes visual assessment, weld continuity checks, and dimensional verification. For high-demand applications, we implement non-destructive testing methods such as ultrasonic or penetrant inspection. Weld quality is documented and compared against acceptance criteria to ensure consistency across production runs.

Process parameters including voltage, wire feed rate, shielding gas flow, and weld speed are recorded for traceability. Each welder follows standardized procedures supported by training and qualification programs. Calibration of welding equipment is performed regularly to maintain consistent output. Custom welding assembly parts are inspected at multiple stages: pre-welding, in-process, and post-weld. Dimensional conformity, joint penetration, and structural integrity are verified against reference drawings and production specifications.

Corrective actions and quality improvement plans are executed promptly in case of deviations. We maintain documentation for batch tracking, operator identity, and weld sequence, ensuring that every Custom welding assembly can be traced back to its production history.

5. Application Flexibility and Industrial Compatibility

Our Custom welding assembly solutions are used in automotive, furniture, construction, energy, and consumer electronics industries. Each assembly is designed to meet the specific mechanical, aesthetic, and thermal requirements of its target environment. We manufacture mounting frames, structural brackets, enclosures, and multi-part support systems used in dynamic and static applications.

Automotive components require vibration resistance and impact tolerance, which we achieve through controlled weld depth and reinforcement strategies. Furniture frames demand a clean visual finish, prompting us to use low-spatter techniques and post-weld polishing. For construction and industrial support systems, we focus on load-bearing capacity and corrosion resistance, adjusting weld placement and joint design accordingly.

Our Custom welding assembly service is adaptable to low and high-volume orders, supporting both prototype validation and mass production. The same assembly process applies to diverse product categories by adapting fixture design and weld path programming. We maintain the flexibility to switch between product types or material grades without compromising weld quality.

6. Engineering Support and Production Scalability

We collaborate with engineers, designers, and procurement teams to streamline the development and production of Custom welding assembly parts. We offer support from early-stage design through to final inspection, helping optimize frame layout, joint design, and material selection. Our team uses CAD modeling and digital simulation tools to predict thermal behavior, distortion potential, and fixture needs.

Rapid prototyping services are available to validate new product designs. During pilot runs, we identify optimization opportunities in weld sequence, fixturing, and handling. For repeat orders, we create dedicated jigs and fixtures to minimize setup time and improve output consistency. Our Custom welding assembly workflow is built for scalability and precision.

With in-house machining, cutting, forming, welding, and finishing capabilities, we reduce lead times and improve control over each stage of production. This integrated workflow minimizes the risk of dimensional mismatch or process delay. Each Custom welding assembly benefits from consolidated engineering knowledge and a responsive production team capable of meeting evolving design changes or urgent deadlines.