Steel Spot And Seam Welding Processing Servcie Stainless Steel Aluminum Sheet Metal Tube Welding Assembly Frame

We specialize in providing sheet metal tube welding solutions using advanced spot welding service methods for stainless steel and aluminum structures. Our operations focus on joining metal sheets and tubular components with precision and strength, meeting the technical demands of industries requiring stable and uniform welding assemblies. We employ multiple spot welding service techniques combined with seam welding to deliver high-quality metal frame assemblies, enabling seamless structural performance across various industrial applications. From initial metal preparation to post-welding finishing, our workflow ensures consistent control throughout every stage of the spot welding service.

Key attributes

Other attributes

Packaging and delivery

Supply Ability

Lead time

| Quantity (pieces) | 1 - 50000 | > 50000 |

| Lead time (days) | 35 | To be negotiated |

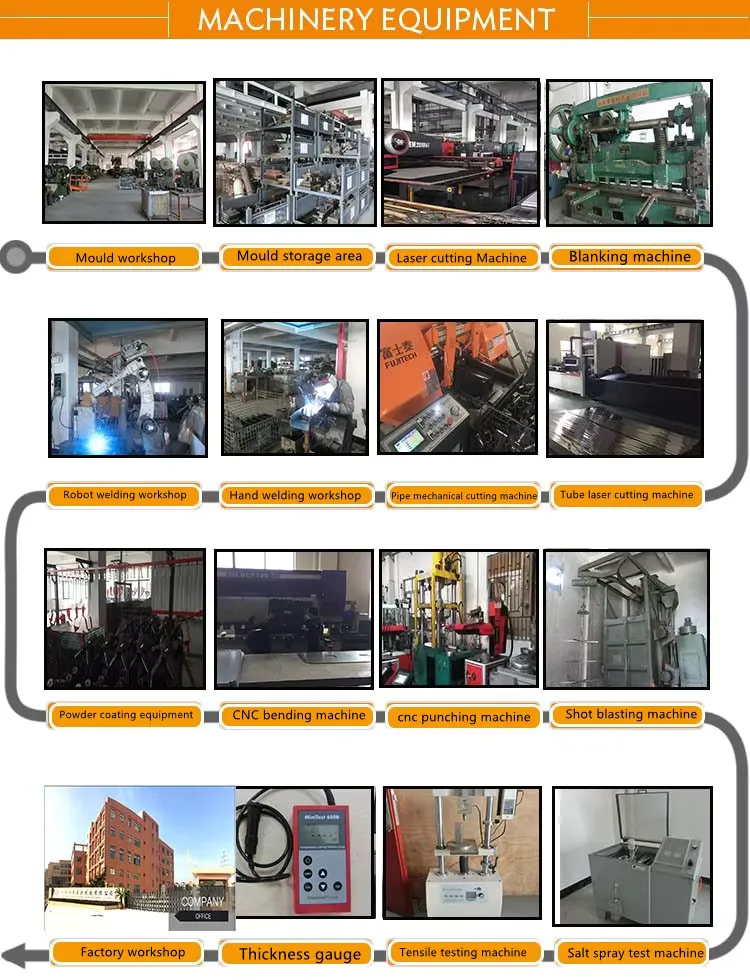

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

| Our advantage for metal fabrication | a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Materials | Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. |

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

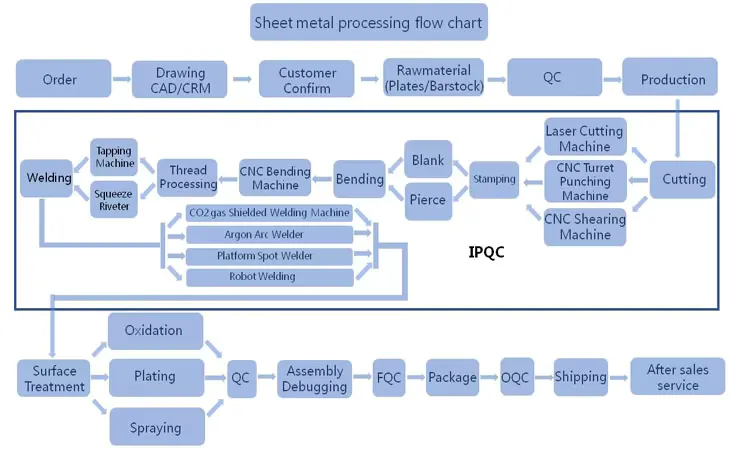

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

1. Specialized Spot Welding Capabilities

We apply controlled heat and pressure using electrode-based welding systems that are optimized for both stainless steel and aluminum. Our spot welding service includes single-point welds, multi-spot sequences, and programmable weld paths to accommodate different joint configurations. We adapt the weld settings such as current, time, and electrode force based on the material type and thickness to guarantee weld integrity without material distortion.

Our spot welding service enables us to create robust lap joints for tubular and flat sheet connections. The repeatability of our automated spot welding systems ensures precise weld locations with minimal human error. Stainless steel assemblies benefit from concentrated heat input for strong joint formation, while aluminum structures are handled with advanced waveform control to address their higher thermal conductivity and oxidation behavior.

We manage electrode wear, surface cleanliness, and pressure distribution to achieve consistent weld nugget formation. This control results in assemblies with reliable mechanical performance, even under dynamic loading or thermal stress.

2. Seam Welding for Continuous Joint Strength

In addition to discrete point welding, we use seam welding as a complementary method for applications that demand continuous metal fusion. Seam welding involves overlapping electrodes rolling along the weld line, creating a series of overlapping spot welds or a near-continuous weld seam. Our spot welding service integrates this process for tubes, frames, and enclosures that require leak-proof or load-bearing connections.

We configure seam welding machines with synchronized rotation and weld pulses to ensure uniform bead formation. This process is ideal for circular tubes, rectangular frames, and high-integrity joint paths. Seam welding contributes to aesthetic consistency and eliminates the need for secondary sealing processes. As part of our spot welding service, seam welding helps us meet specialized requirements in automotive, HVAC, and appliance sectors where joint continuity is critical.

We tailor seam weld penetration and spacing based on load analysis and thermal expansion characteristics. Our technicians monitor electrode alignment and cooling systems to prevent overheating, material warping, or weld failure during extended operations.

3. Frame and Tube Assembly Integration

We use our spot welding service to fabricate complete assemblies involving tubes, sheet panels, and supporting brackets. These frame assemblies are used in structural housings, racks, chassis, and industrial enclosures. We prepare each component with reference points, guide slots, or pre-cut tabs to ensure accurate positioning during the welding process.

Each assembly project begins with part fit-up verification. We use jigs and fixtures designed in-house to maintain alignment, squareness, and spacing. Spot welding service allows us to rapidly tack and fix components in place, reducing handling time and improving dimensional accuracy. For tubular connections, we apply welds at strategic stress points to optimize load distribution and mechanical rigidity.

Our technicians perform weld sequence planning to minimize heat concentration and residual stress. This level of process control supports tight flatness and alignment tolerances across welded structures. For assemblies that involve both spot and seam welding, we define transition zones and optimize the weld overlap to ensure smooth structural continuity.

4. Surface Preparation and Finishing

We treat each weld surface with care before and after welding to ensure cleanliness, conductivity, and post-process compatibility. Before applying our spot welding service, we remove surface contaminants such as oil, oxide, and residue using brushing, degreasing, or mechanical abrasion methods. Clean surfaces ensure reliable current transfer during welding and prevent defects such as porosity or spatter.

After welding, we inspect and treat welded areas to meet appearance and performance criteria. We remove any excess weld flashes or discoloration and prepare the assemblies for downstream coating or painting processes. Our spot welding service ensures minimal surface deformation, preserving the overall aesthetic and structural integrity of the metal parts.

We also offer optional edge rounding, polishing, or grinding based on application needs. For aluminum parts, we ensure no oxidation residue remains post-welding, maintaining clarity for any anodizing or finishing operations.

5. Process Monitoring and Quality Assurance

Our spot welding service is backed by a rigorous quality assurance system. We inspect each weld location visually and mechanically, using spot check tools, force gauges, and peel tests to evaluate weld strength and consistency. For critical components, we perform destructive testing during first article inspection to verify nugget size and joint reliability.

Weld parameters including time, current, electrode pressure, and cooling rate are tracked and recorded for process traceability. We apply welding schedules based on standard libraries refined through extensive trials and operator experience. All welding machines used in our spot welding service are calibrated routinely, and electrodes are dressed or replaced to maintain consistent weld quality.

We use in-line monitoring systems for high-volume production, where electrode wear and part fitment are tracked automatically. Rejected parts are quarantined, and root cause investigations are conducted when any anomalies are detected. Our spot welding service includes pre-production approval, mid-batch sampling, and end-of-line audits to meet internal and customer-defined quality criteria.

6. Application Diversity and Custom Support

Our spot welding service supports multiple industries including automotive, consumer electronics, energy systems, construction, and furniture manufacturing. The ability to rapidly and securely join sheet metal and tubular components allows us to respond flexibly to evolving market needs. From mounting brackets to safety enclosures, we apply spot welding service techniques that prioritize efficiency, repeatability, and structural durability.

We collaborate closely with engineers and designers to optimize weld placement, joint configuration, and material selection during the design stage. Our engineering team uses CAD data and simulation tools to plan electrode paths, cooling cycles, and fixturing requirements in advance. This proactive approach ensures the welding process is aligned with overall product functionality and manufacturing constraints.

Whether the project involves low-volume prototypes or high-volume production, we scale our spot welding service accordingly. We maintain stock of standard materials and adjust machine setups to minimize lead times. By integrating cutting, forming, and welding operations in-house, we offer streamlined manufacturing with full control over each stage of the process.