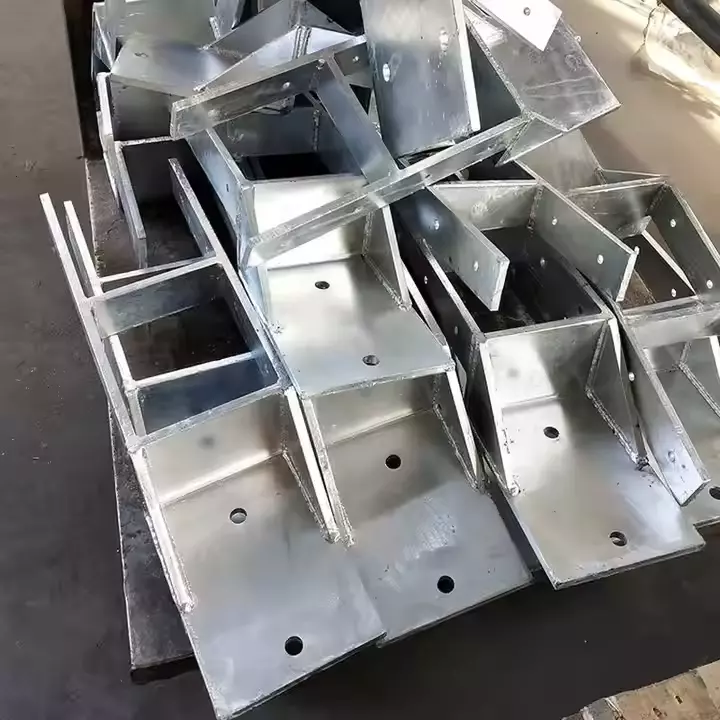

OEM Factory Direct Metal Welding Services Custom Sheet Metal Fabrication Stamping Sheet Metal Parts

We specialize in OEM factory direct services for metal welding, custom sheet metal fabrication, and precision stamping for sheet metal parts. Our experience in industrial metalworking allows us to deliver consistent quality, functional designs, and stable structural results across every project. As a professional provider of Steel welding service, we integrate precision welding, tailored fabrication, and forming techniques to support a wide range of industries with customized and structurally sound metal components.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Features

1, One-stop solution

2, Tools designed and built in house

3, Fully equipped & Trained

4, Consistent quality

5, Turnkey manufacturing services

6, Excellent communication ability

7, Professional & Efficient response

| Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, Tube & Pipe & Rod |

| Processing | Cutting, Stamping, CNC Bending, Welding, Threading, Polishing, Assembly, etc |

| Surface Treatment | Brushing, Polishing, Vacuum Plating, Anodizing, Powder Coating Plating, Sandblast |

| logo | Stamp, Silk print, Laser marking, UV print, Multicolor pad printing. |

| Size | Customized |

| Color | White, black,silver, red, grey etc RAL, Pantone, RGB, CMYK. |

| Software | CAD, Solidworks, CATIA, UG, PRO-E. Inventor, AI |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft. |

| Sample lead time | No surface treatment, 1-7 workdays.Require surface treatment, 3-10 workdays. |

| Pricing Term | FOB, CIF, DDU etc |

| Port of Loading | Shanghai or Ningbo |

| Market | North America, Europe, Oceania, Asia, South America |

1. Material Expertise and Adaptability

We select materials based on the specific requirements of each project, ensuring structural stability, corrosion resistance, and welding compatibility. Our expertise in Steel welding service allows us to work with mild steel, carbon steel, stainless steel, and alloy sheets with varying thicknesses. These materials are pre-treated to ensure clean weld zones, improve penetration consistency, and reduce residual stresses.

We understand that sheet metal responds differently under thermal conditions, and we carefully manage deformation through controlled heat application and fixturing. The base materials are analyzed for welding suitability, including grain orientation, oxide layer control, and metallurgical integrity to maintain weld quality.

With a focus on structural consistency, we ensure that every welding joint on fabricated steel parts contributes to the durability of the entire assembly. Our Steel welding service adapts to high-strength steels and engineered alloys, enabling tailored mechanical properties and dependable service life.

2. Welding Technology and Process Integration

We utilize a range of welding technologies to meet various structural and design needs. Our Steel welding service capabilities include MIG, TIG, spot welding, and laser welding processes, each selected based on penetration depth, thermal influence, and finish quality requirements.

For thin-gauge sheet metal, we apply pulsed MIG welding to control warping and ensure fine weld beads. For heavier assemblies, we use multi-pass welding techniques to maintain structural integrity without over-penetration. Laser welding is employed in cases where minimal distortion and high-speed processing are required.

Our welding teams operate in controlled environments with precision jigs and fixtures, ensuring alignment, repeatability, and dimensional accuracy. Every step of our Steel welding service is planned in advance using CAD modeling and weld simulation software to eliminate defects such as porosity or incomplete fusion.

By combining forming, cutting, and joining in one workflow, we deliver complete metal parts with minimized handling and maximum precision. Every welded joint supports the mechanical intent of the final component, whether it serves as a load-bearing structure or an enclosure.

3. Custom Sheet Metal Fabrication and Stamping Capability

We provide fully customized sheet metal solutions that combine forming, stamping, and Steel welding service into a single production process. This ensures dimensional accuracy, part repeatability, and compatibility with downstream assembly.

Our stamping operations include blanking, coining, punching, and deep drawing, and are integrated with bending, flanging, and forming procedures. These stamped parts are prepared for welding through precise trimming, chamfering, and edge conditioning to ensure clean weld zones and reliable joint formation.

The Steel welding service seamlessly joins these stamped or bent components, resulting in complete assemblies such as brackets, mounts, housings, and structural frames. Every component is produced to maintain its designed geometry during and after the welding process, with distortion management and tolerance monitoring applied at every stage.

We work closely with our clients to analyze assembly requirements and select the most efficient forming and joining methods. Our process flexibility allows for high-mix, low-volume production runs as well as scalable high-volume output while maintaining consistent quality.

4. Quality Assurance and Welding Inspection

We enforce strict quality control over our Steel welding service, using in-process checks and final inspection protocols to verify mechanical integrity, dimensional compliance, and visual appearance. Every weld is monitored for penetration, alignment, and consistency using both manual and automated inspection systems.

Our inspection techniques include dye penetrant testing, weld profile scanning, ultrasonic testing, and dimensional verification. All welded components are assessed for strength, fatigue resistance, and thermal stability to ensure their suitability for end-use environments.

As part of our Steel welding service, we also monitor joint cleanliness, slag removal, and spatter reduction, resulting in clean and visually acceptable welds. Weld sequence documentation and operator certification further reinforce our ability to maintain reliable and repeatable results across different product batches.

We trace each production stage from material entry to final delivery, offering full transparency and control over each part’s manufacturing history. This traceability reinforces trust in the performance and consistency of our steel welded parts.

5. Application Scenarios and Industry Use

Our Steel welding service supports a wide range of industry sectors including automotive, electrical enclosures, industrial machinery, furniture frames, and architectural components. We fabricate custom welded parts that are designed for static load support, vibration resistance, and multi-component integration.

In automotive applications, we produce welded mounts, reinforcement brackets, sensor frames, and enclosure panels. For electrical equipment, we provide welded sheet metal housings, battery trays, control boxes, and support chassis. Our Steel welding service ensures that each component meets the strength and dimensional requirements of its specific function.

Industrial equipment often relies on welded steel frames, guards, and conveyor supports. In the furniture sector, we manufacture welded chair frames, table bases, and display racks that offer both strength and aesthetic form. We also serve HVAC, medical devices, and agricultural equipment, tailoring welded parts for functionality, weight efficiency, and corrosion resistance.

Our experience in Steel welding service enables us to fabricate parts that function in both dynamic and stationary environments. We accommodate custom surface finishes such as powder coating, plating, and paint-ready welding, adding flexibility to each component’s final appearance and usability.

6. Production Support and Engineering Collaboration

We provide complete engineering support during the design and manufacturing process. Our Steel welding service is backed by design review, prototype validation, fixture development, and continuous improvement practices. We collaborate with clients to optimize joint design, minimize material waste, and simplify manufacturing steps.

All our welding operations are supported by 3D CAD modeling, thermal distortion analysis, and process simulation. This allows us to anticipate potential issues before production begins. Our fixture and jig development ensures part alignment and welding consistency, especially for multi-part assemblies and irregular shapes.

Our team assists with prototype runs and quickly transitions successful samples into full-scale production. Our Steel welding service includes documentation of welding procedures and visual standards for repeatability. We also provide welding strength testing, compliance certification, and project reports as needed.

Whether the project involves small brackets or full structural frames, we offer responsive technical support, material sourcing guidance, and efficient production management to ensure a successful outcome for every welded sheet metal part.