Customized Service Stainless Steel Aluminum Sheet Metal Welding Manufacturing Steel Products

We provide customized service for stainless steel and aluminum sheet metal welding manufacturing steel products, ensuring high precision and quality in every stage of production. Our expertise in seam welding service allows us to join metal components with accuracy and durability, creating strong and reliable steel products suitable for various industrial applications. We apply advanced welding technologies and strict process controls to meet the specific requirements of each project.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Our advantage for metal fabrication | a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

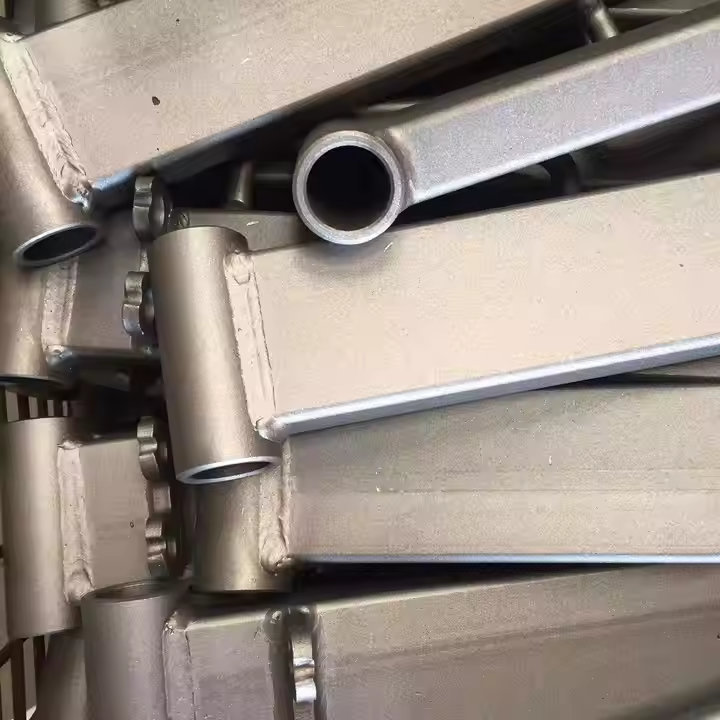

| Carbon steel, Aluminium or Stainless Steel tube or sheet pieces. | |

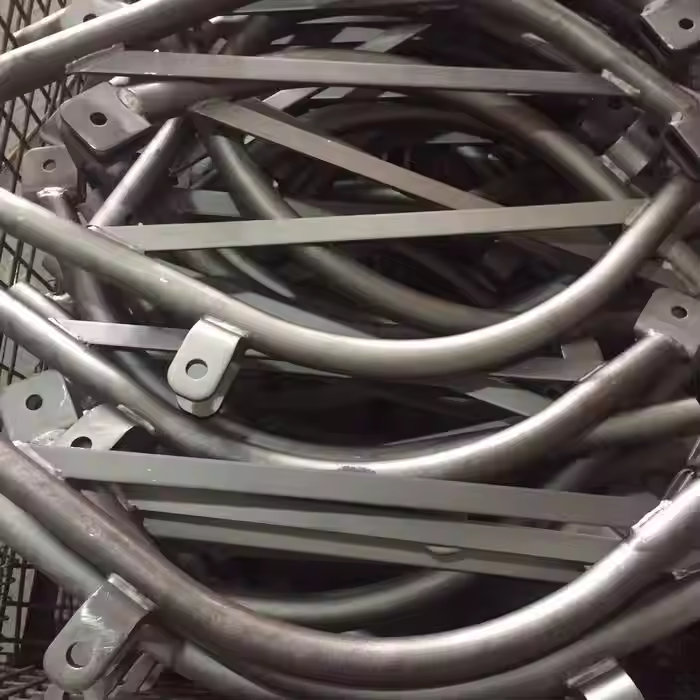

| Usage | Agricultural machine ,Machinary, fitness equipment, stoller or scooter frame, other industrial/commerical equipments. |

| Molds | Produced by factory own to ease the control of quality and lead time as well as save the cost. |

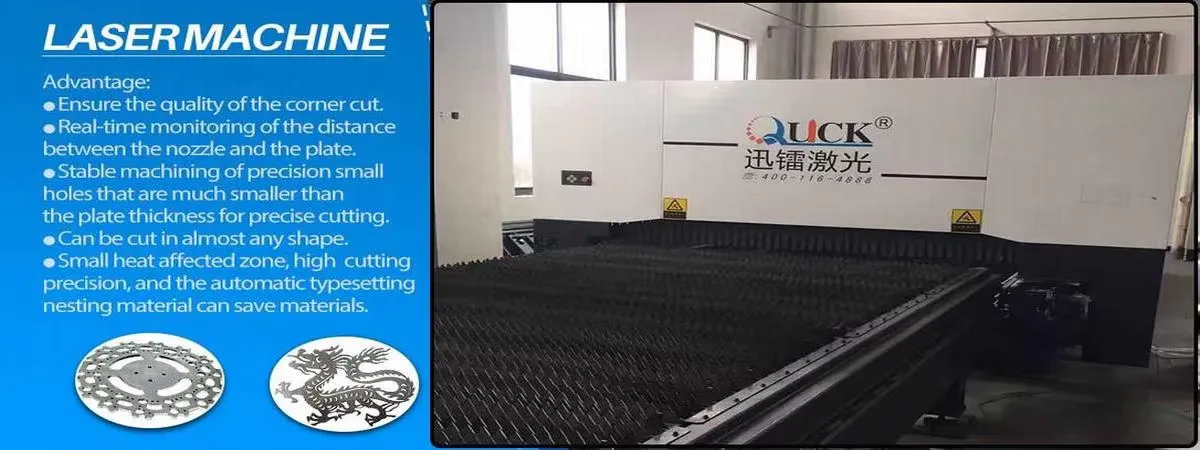

| Mfg Process | Cutting, bending/folding, stamping/punching, welding, polishing, surface treament. |

| Tolerance | ±0.2MM in size and ±1 degree in bending angle, or follow other critiera required by customer. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Color | Optional with various colors as required by customer. |

| OEM | Yes, can produce based on customer's drawings or samples. |

| Lead time | 15-20days for mold and 30days for first lot. |

Precision in Seam Welding Service

Our seam welding service employs state-of-the-art equipment to produce continuous, high-strength welds that ensure structural integrity. We focus on maintaining consistent weld quality across stainless steel and aluminum sheet metal products, which is crucial for applications requiring leak-proof and durable joints. The precision offered by our seam welding service enhances the performance and longevity of the steel products we manufacture.

Material Versatility and Compatibility

We work extensively with stainless steel and aluminum, two materials favored for their corrosion resistance and mechanical properties. Our customized service accommodates different grades and thicknesses of sheet metal, adapting the seam welding service parameters accordingly. This versatility allows us to fabricate steel products that meet diverse needs in sectors such as automotive, aerospace, electrical, and construction.

Customized Fabrication and Assembly

We offer tailored solutions that combine sheet metal cutting, forming, and seam welding service into an integrated manufacturing process. This customization ensures that the final steel products meet precise design specifications and functional requirements. Our ability to customize the welding process, including seam welding service, ensures seamless integration of components into assemblies or finished products.

Quality Control and Reliability

Throughout the manufacturing process, rigorous quality control measures are implemented to guarantee the consistency and reliability of welded joints. We perform non-destructive testing and inspections to verify the integrity of the seam welding service, ensuring the steel products meet industry standards and customer expectations. This commitment to quality enhances product safety and reduces the risk of failure in application.

Efficient Production and Delivery

Our manufacturing setup is designed to optimize workflow from sheet metal preparation to welding and finishing. The customized service approach enables us to handle various order sizes with flexibility while maintaining efficiency. By streamlining seam welding service within the production line, we minimize lead times and provide timely delivery of steel products without compromising quality.

Applications Across Industries

The stainless steel and aluminum sheet metal products fabricated through our customized welding manufacturing service, including seam welding service, are widely used in many industries. These products serve essential roles in automotive frames, electrical enclosures, aerospace components, and architectural structures. Our welding manufacturing expertise ensures that these steel products perform reliably under demanding conditions.