High Quality Aluminum Fabrication Stamping Service Welding Processing Assembly Part

- Customized

- China

- in 35days

We provide high quality aluminum fabrication stamping service with integrated aluminum welding assembly, focusing on delivering reliable, precise, and durable aluminum parts. Our aluminum welding assembly process ensures strong bonds between fabricated stamped components, enhancing overall structural integrity. Through our aluminum welding assembly expertise, we guarantee consistent performance suitable for various industrial applications.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

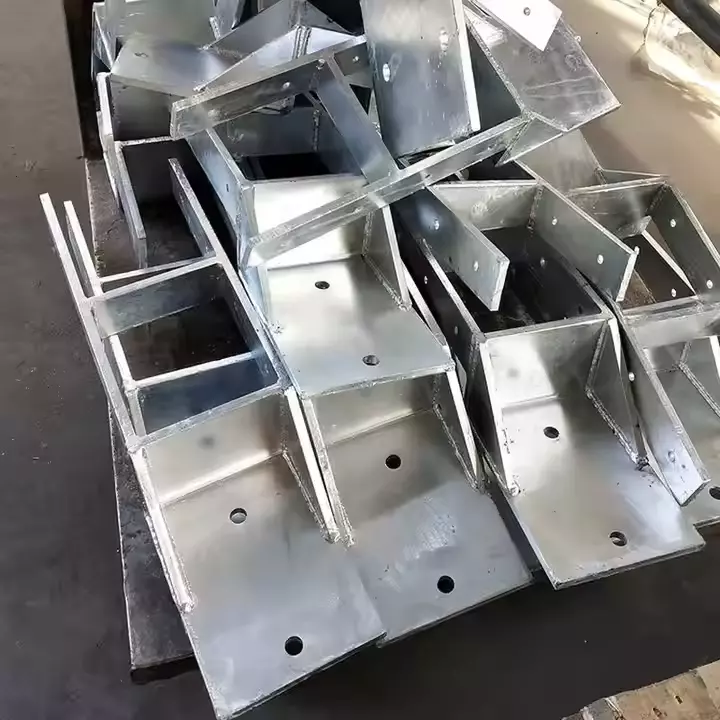

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

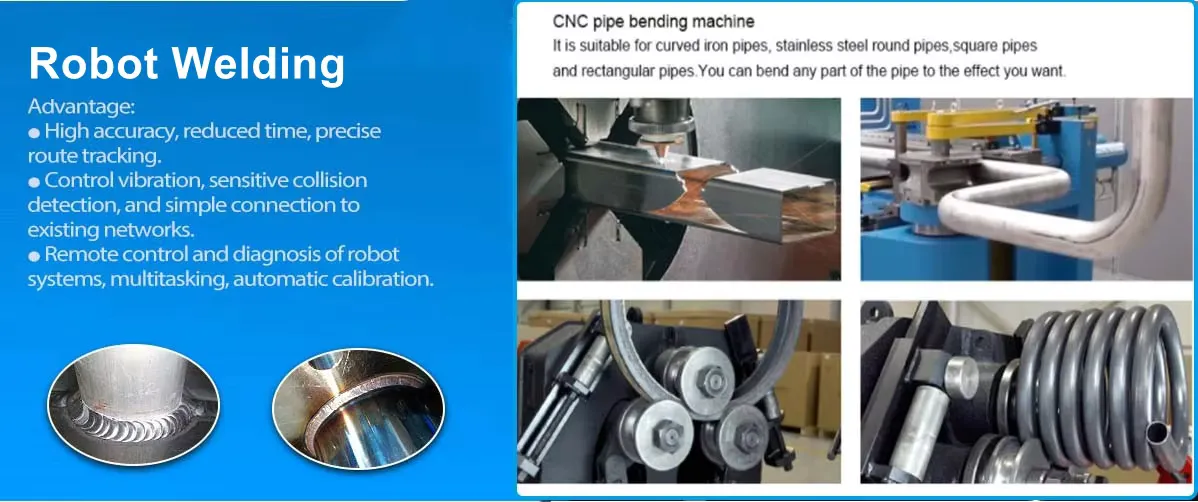

Precision Aluminum Fabrication Stamping

The aluminum fabrication stamping process is designed for accuracy, producing parts that perfectly fit during aluminum welding assembly. This precision reduces the need for adjustments and supports seamless welding.

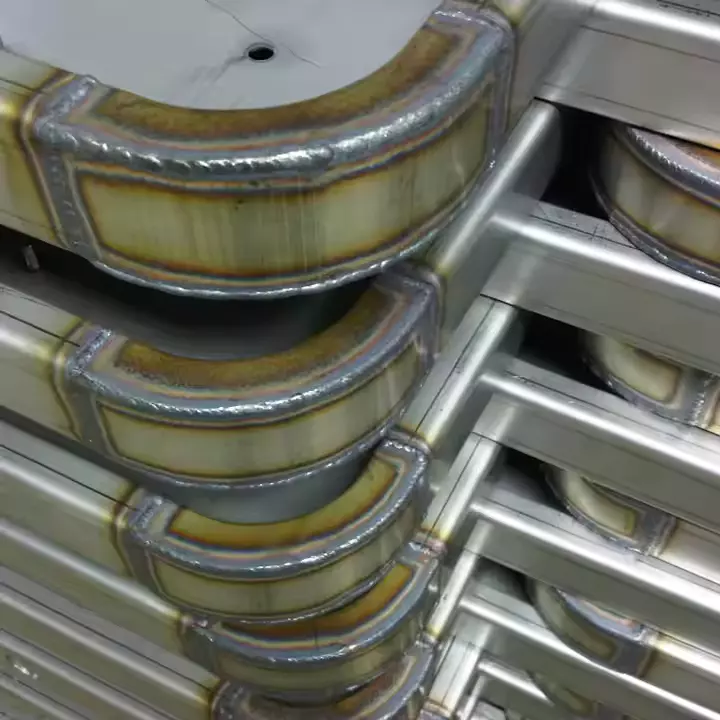

Advanced Welding Techniques

We use specialized welding methods suitable for aluminum, such as TIG and MIG, to ensure strong and clean joints during aluminum welding assembly. Proper control of welding parameters minimizes defects and improves product longevity.

Structural Integrity and Assembly

Our aluminum welding assembly employs fixtures that maintain alignment, enhancing mechanical strength. This ensures the final product can withstand demanding applications without failure.

Surface Treatment Post-Assembly

After aluminum welding assembly, parts undergo surface treatments like anodizing or powder coating. These treatments protect the aluminum and enhance appearance, with minimal distortion thanks to precise welding.

Quality Control Processes

Throughout aluminum welding assembly, we conduct inspections and testing to ensure weld quality and dimensional accuracy. Continuous monitoring allows us to maintain high standards and optimize processes.

Custom Solutions for Diverse Industries

Our aluminum welding assembly services support industries including automotive, aerospace, electronics, and construction. We work closely with clients to meet specific requirements from prototypes to full production runs.