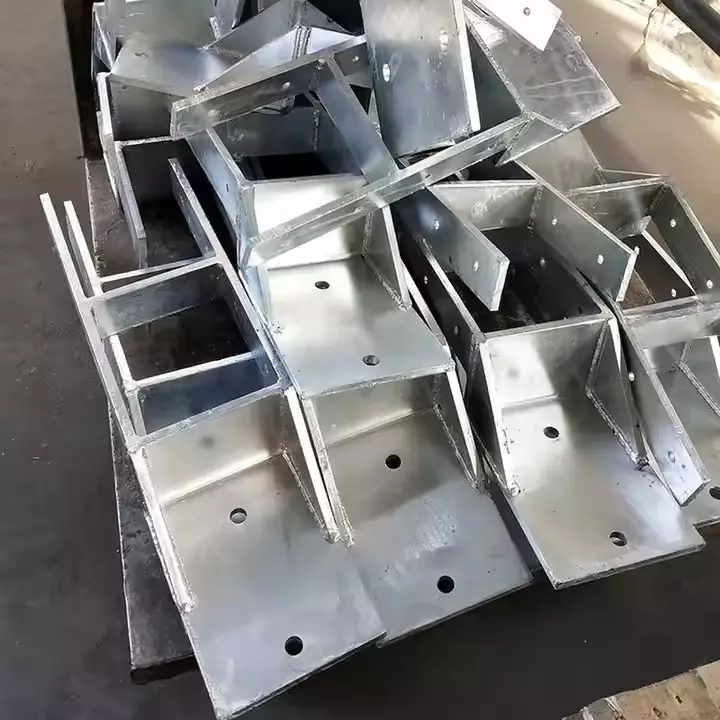

Custom Welding And Assembly Fabrication Service Oem Sheet Metal Frame

We provide custom welding and assembly fabrication service focused on OEM sheet metal frames. Our expertise covers the full spectrum of welded assembly service processes, including cutting, bending, welding, and final assembly of metal components. This integrated approach ensures high-quality, durable, and precise sheet metal frame products tailored to customer requirements.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

Comprehensive Welding Techniques

Our welded assembly service incorporates a variety of welding methods suitable for different metals and applications. These include MIG, TIG, spot welding, and seam welding, which are selected based on material type and thickness. Each technique is executed with precision to ensure strong, clean joints that maintain the structural integrity of the sheet metal frame. Our welding process is optimized to reduce heat distortion and improve the overall finish.

Precision Fabrication and Cutting

We utilize advanced cutting technologies such as laser cutting and CNC machining to produce sheet metal parts with exact specifications. This precision is critical for the accuracy of the welded assembly service, as well-cut components fit together seamlessly during the welding and assembly stages. The combination of precise cutting and expert welding contributes to the consistent quality and performance of the final sheet metal frames.

Custom Bending and Forming

Our custom bending and forming capabilities allow us to shape sheet metal parts into complex geometries required by OEM sheet metal frames. Using CNC press brakes and rolling machines, we achieve accurate bends and curves that conform strictly to design parameters. This capability is essential for producing welded assembly service products that meet both functional and aesthetic demands.

Material Selection and Quality Assurance

We work with a range of metals including carbon steel, stainless steel, and aluminum, chosen to meet specific mechanical and environmental requirements. Our welded assembly service includes rigorous quality control measures at each stage, from material inspection through to final assembly. Dimensional checks, weld inspections, and performance testing ensure that each sheet metal frame meets high standards of durability and reliability.

Assembly Integration and Testing

Our welded assembly service extends beyond welding to include complete assembly of sheet metal frames and associated components. We ensure that all parts are accurately aligned and securely fastened, ready for integration into larger systems or finished products. Functional testing and inspections are conducted to verify the structural integrity and operational performance of the assembled frames, supporting customer satisfaction and product longevity.

Surface Treatment and Finishing

To enhance corrosion resistance and appearance, we offer various surface treatments such as powder coating, galvanizing, and painting. These finishing processes are carefully applied to welded assembly service products to improve durability and provide an attractive surface finish. The treatments are selected based on the metal type and the intended application environment, contributing to the overall quality of the sheet metal frames.