Customized Stainless Steel Shell Chassis Cabinet Sheet Metal Shell Thickened Stainless Steel Sheet Metal Welding Manufacturers

We specialize in sheet metal manufacturing, offering customized stainless steel shell chassis cabinets and thickened stainless steel sheet metal shells with professional welding services. Our expertise in sheet metal manufacturing ensures durable, high-quality products tailored to meet specific industrial applications.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

1. Comprehensive Sheet Metal Manufacturing Expertise

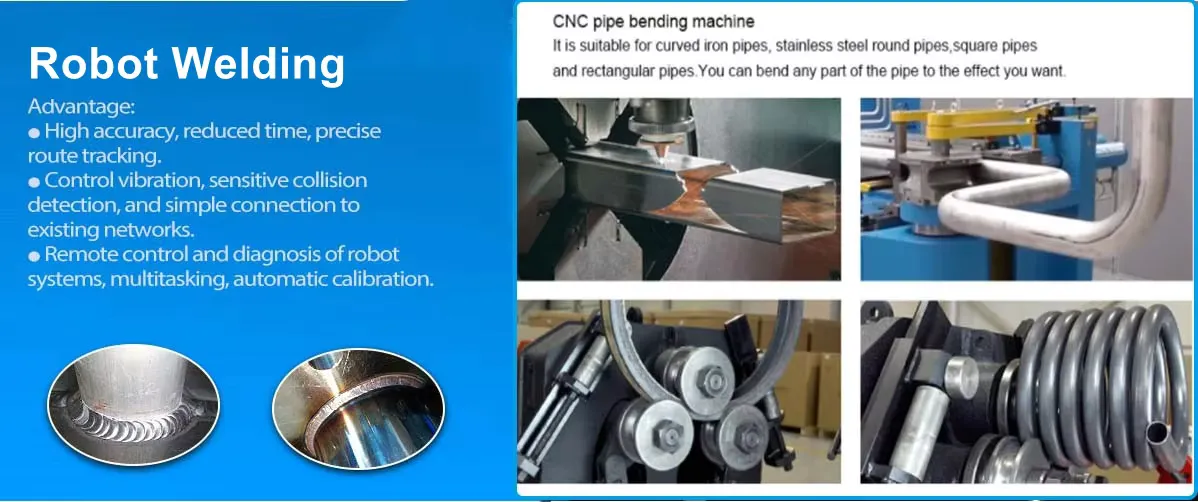

Our sheet metal manufacturing capabilities encompass cutting, bending, welding, and assembly, allowing us to produce complex stainless steel shells and chassis cabinets with precision and consistency. We employ advanced CNC machines and skilled technicians to achieve superior product quality.

2. Material Selection and Thickness Customization

We use premium-grade stainless steel and offer customization in material thickness to enhance strength and durability. The thickened sheet metal shells provide enhanced protection and stability for electronic and mechanical components housed within.

3. Precision Welding and Assembly

Our welding manufacturing process focuses on structural integrity and seamless joints. We utilize TIG and MIG welding techniques to ensure robust connections that maintain the corrosion resistance and mechanical properties of stainless steel.

4. Tailored Design and Engineering Support

Our sheet metal manufacturing team works closely with customers to develop designs that meet functional and aesthetic requirements. We support custom dimensions, structural reinforcements, and finishing details to deliver bespoke stainless steel shell solutions.

5. Surface Finishing and Protection

To protect and enhance the appearance of our stainless steel products, we offer surface treatments such as polishing, passivation, and powder coating. These finishes improve corrosion resistance and provide a professional look suitable for various industrial environments.

Service Scope

Our sheet metal manufacturing services cater to industries including electronics, telecommunications, automotive, and machinery. We focus on delivering durable and precision-engineered stainless steel sheet metal products that meet rigorous application standards.