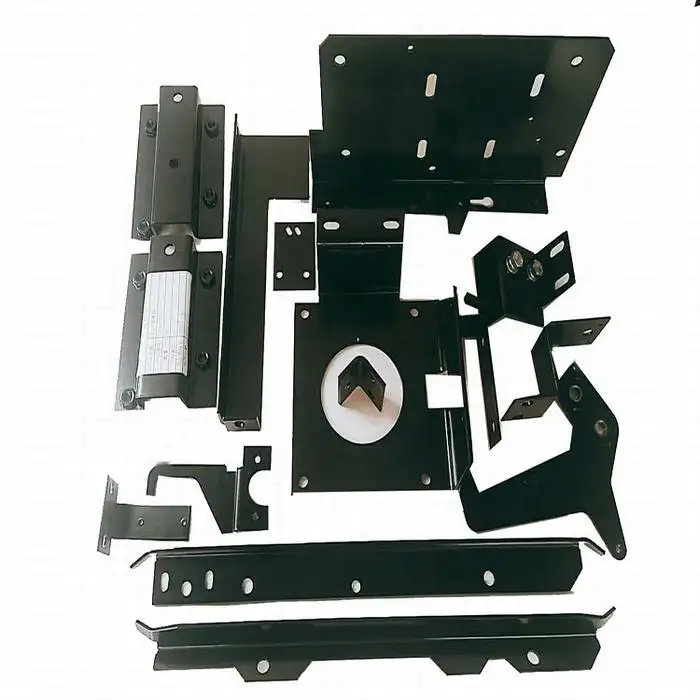

Cutomized Design Sheet Metal Manufacturing Laser Cutting Service Sheet Metal Bending Stamping Parts

We specialize in customized design sheet metal manufacturing, offering comprehensive laser cutting, sheet metal bending service, and stamping parts production. Our expertise in sheet metal bending service ensures precision, repeatability, and high-quality outcomes tailored to meet diverse industrial requirements.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

1. Advanced Sheet Metal Bending Service Capabilities

Our sheet metal bending service uses state-of-the-art CNC press brakes and bending machines to achieve accurate angles and consistent bends. This precision ensures parts meet strict dimensional tolerances and functional specifications required in complex assemblies.

2. Integration with Laser Cutting and Stamping

Combining our laser cutting technology with the sheet metal bending service allows seamless production of stamped and bent parts. This integration reduces manufacturing lead times and enhances the overall quality of sheet metal components.

3. Custom Design Support

We work closely with clients to translate their customized design needs into precise sheet metal parts. Our sheet metal bending service supports various materials and thicknesses, accommodating complex geometries and innovative product designs.

4. Material Versatility and Quality

Our sheet metal bending service handles a wide range of metals including carbon steel, stainless steel, aluminum, and brass. We ensure the bending process preserves the material’s mechanical properties and surface quality.

5. Application in Diverse Industries

Our sheet metal bending service products are used extensively in automotive, electronics, machinery, and construction sectors. We focus on delivering parts that provide structural integrity and functional reliability in demanding applications.

Service Scope

Our sheet metal manufacturing service includes laser cutting, bending, stamping, and finishing operations, designed to provide end-to-end sheet metal fabrication solutions for various industrial needs.