High Quality Sheet Metal Fabrication Laser Cutting CNC Bending Forming Welding Processing Custom Metal Cover

We provide high-quality stainless steel sheet metal fabrication services tailored to the production of custom metal covers with complex geometric requirements and superior surface finish. Our capabilities span laser cutting, CNC bending, forming, welding, and precision processing, ensuring consistency across every production stage. Each custom metal cover undergoes rigorous control throughout the stainless steel sheet metal fabrication process to meet aesthetic and functional expectations across various industries.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling, |

| or Robot stamping tooling | |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc |

| 1) AL1060, AL6061, AL6061, AL5052 | |

| 2) Steel, mild steel, SPCC | |

| 3) SS201, SS303, SS304, SS316, SS316L | |

| 4) SPTE, galvanized sheet | |

| 5) Brass, copper | |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes, |

| Solar Energy, Construction etc, |

1. Precision Laser Cutting for Complex Stainless Steel Structures

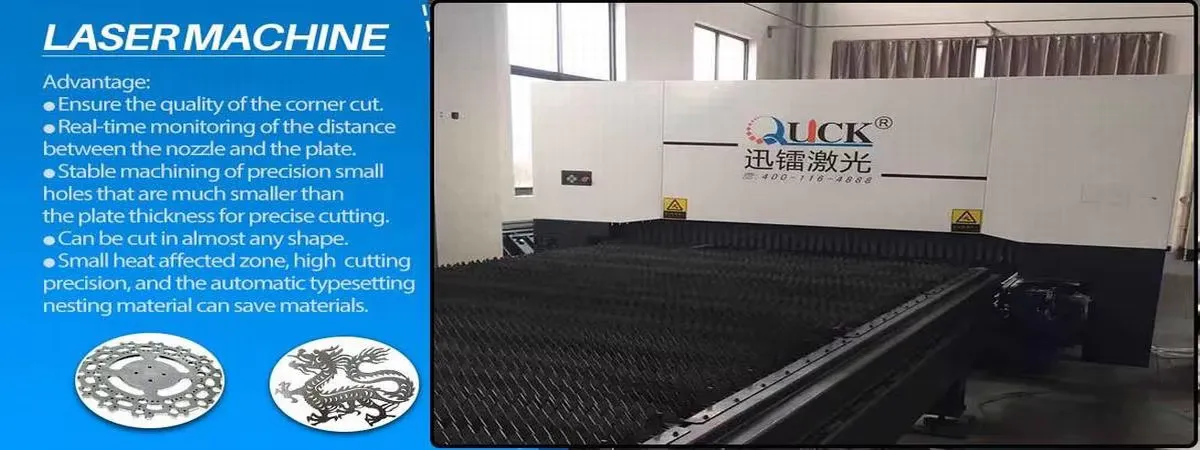

Our stainless steel sheet metal fabrication begins with high-precision laser cutting, which allows us to shape stainless steel sheets into intricate profiles with smooth edges and minimal thermal distortion. We use advanced laser systems capable of cleanly cutting stainless steel in various thicknesses, accommodating small holes, detailed outlines, and tight tolerances.

Throughout the stainless steel sheet metal fabrication process, laser parameters are customized based on sheet thickness and edge quality requirements. This ensures that the custom metal covers we produce maintain consistency in size and contour. We utilize this capability not only for batch production but also for prototype development and custom one-off items. Clean laser edges reduce the need for secondary deburring, saving processing time while maintaining high-quality finishes.

In every project involving stainless steel sheet metal fabrication, we emphasize accuracy and reproducibility, making laser cutting a foundational stage in achieving the structural integrity of each metal cover.

2. CNC Bending and Multi-Axis Forming for Dimensional Accuracy

We apply CNC-controlled bending equipment to shape stainless steel components with high dimensional precision. Our bending operations are essential in stainless steel sheet metal fabrication, especially when producing custom metal covers that require multi-fold angles or enclosure shapes. Our technicians program complex bend sequences to eliminate inconsistencies and spring-back commonly associated with stainless steel.

We support small-radius bends, Z-shaped structures, and U-shaped enclosures with repeatable precision. During stainless steel sheet metal fabrication, each part is fixtured and aligned to reduce tolerance stack-up. We also simulate bending operations beforehand to identify strain points and apply compensation as needed. Stainless steel’s elastic modulus and grain direction are factored into our programming for optimal forming accuracy.

By using multi-axis CNC press brakes, we minimize operator dependence and maximize repeatability across multiple units. Our commitment to precision at the forming stage ensures that the final custom metal covers match their design intentions without requiring post-bend reworking. The CNC bending stage forms a critical phase in our stainless steel sheet metal fabrication workflow.

3. Welding and Structural Assembly for Functional Integrity

Our stainless steel sheet metal fabrication services include MIG, TIG, and spot welding tailored for stainless steel. We recognize that welding stainless steel requires strict control over heat input and shielding gas to prevent contamination and maintain corrosion resistance. Our welders apply clean welding techniques to ensure strong, aesthetically consistent weld seams on each custom metal cover.

We develop dedicated fixtures for complex weld assemblies, preventing warping and preserving dimensional accuracy. Our welding process includes butt welding, fillet welding, and flange welding depending on the design of the metal cover. In stainless steel sheet metal fabrication, we ensure that joints remain structurally sound without compromising the overall design.

Post-welding, we smooth weld beads with mechanical grinding and polishing. Our team verifies weld penetration and integrity using visual inspection, penetrant testing, and destructive sampling when required. These processes ensure long-term strength and durability in the stainless steel sheet metal fabrication result.

We also support welded assemblies with spot-welded stiffeners, hinge mounts, or bracket reinforcements where necessary, creating a complete and stable custom metal cover suitable for enclosures, control panels, or architectural applications.

4. Surface Finishing for Visual Uniformity and Corrosion Resistance

In stainless steel sheet metal fabrication, surface finishing is crucial not only for appearance but also for enhancing performance in harsh environments. We offer a full range of stainless steel finishes including brushing, mirror polishing, sandblasting, and passivation. Each finishing method is selected based on the final application of the custom metal cover.

Before surface treatment, we thoroughly degrease and clean each component to ensure adhesion and uniformity. Our brushing process creates a linear grain aesthetic ideal for visible covers, while mirror polishing suits decorative applications. Sandblasting removes oxide layers and gives a matte texture, improving paint or coating adhesion when needed.

During stainless steel sheet metal fabrication, we maintain environmental and process controls to prevent contamination and preserve the metal’s corrosion resistance. For applications that demand chemical resistance or biomedical compliance, we perform passivation treatments using controlled acid baths.

We document surface finish specifications and match them against visual inspection standards, guaranteeing uniformity across batches. These finishing capabilities allow us to supply aesthetically consistent and corrosion-resistant stainless steel covers through every stage of stainless steel sheet metal fabrication.