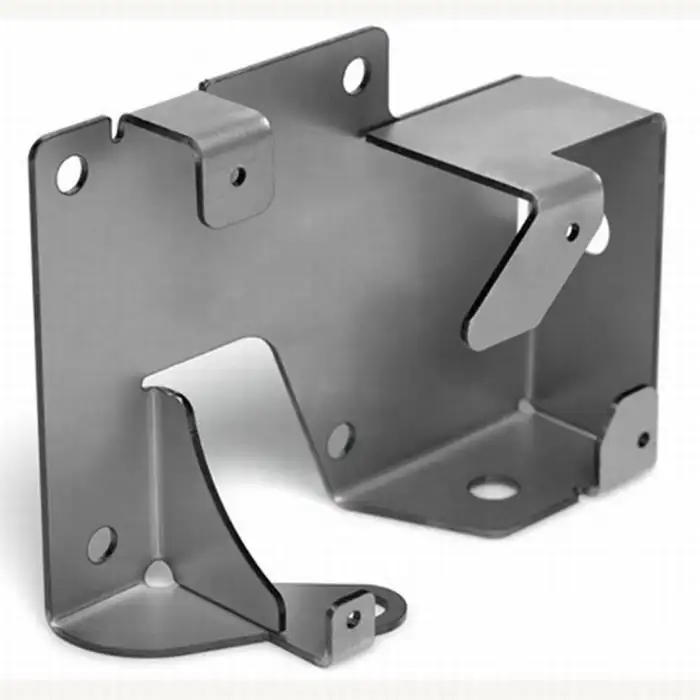

Oem Custom Sheet Metal Fabrication Aluminum Steel Laser Cutting Bending Assemble Metal Electrical Box Enclosure

We offer professional OEM services specializing in custom made sheet metal fabrication for aluminum and steel electrical box enclosures. Our comprehensive process includes laser cutting, bending, and precise assembly to produce durable and functional enclosures tailored to customer specifications.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Our advantage for metal fabrication | a. We have our own factory b. We have a 10 people quality control team c. We have our own testing center in our factory d. We accept OEM, we can produce parts according to your drawings or samples e. All our manager have more than 15 years experience |

| Materials | 1) AL1060, AL6061, AL6061, AL5052 etc. 2) Steel, mild steel, SPCC etc. 3) SS201, SS303, SS304, SS316, SS316L etc. 4) SPTE, galvanized sheet etc. 5) Brass, copper etc. |

| Specification | 1) According to customers' drawings 2) According to customers' samples |

| Usage | Agriculture Machinery, Farms, Furniture, Power, Appliance, Auto, Building, Solar Energy, Instrumentation, Medical device. |

| Mold Material | Cr12 |

| Mfg Process | Mold Make,Laser Cutting, bending, stamping/punching, welding,Assembly ,Packing. |

| Finish | Optional with powder coated, zinc-plated, hot-dip galvanized , anodize, electrophoresis and others. |

| Drawing format | DWG, DXF, Stp, Igs, PDF, Jpg, etc. |

| Service Type | OEM&ODM |

1. Material Expertise and Selection

Our custom made sheet metal fabrication focuses on utilizing high-quality aluminum and steel materials. Aluminum provides lightweight and corrosion resistance benefits, while steel offers strength and durability, making the enclosures suitable for various electrical and industrial applications.

2. Advanced Fabrication Techniques

Using CNC laser cutting and bending equipment, we achieve precise dimensions and clean edges in every sheet metal component. This precision is critical for the functionality and assembly fit of the electrical box enclosures.

3. Tailored Customization

We accommodate a wide range of design requirements, including specific sizes, shapes, and thicknesses. Our custom made sheet metal fabrication services are flexible to support prototype development as well as large-scale production runs.

4. Assembly and Structural Integrity

Our skilled assembly team ensures that the metal electrical box enclosures are welded and fastened securely, providing structural strength and stability. The assembly process maintains material properties and ensures reliable enclosure performance.

5. Surface Finishing Options

To enhance protection and aesthetics, we offer various surface treatments such as powder coating, anodizing, or painting. These finishes increase corrosion resistance and improve the appearance of the electrical box enclosures.

Service Scope

Our custom made sheet metal fabrication services cater to industries such as electronics, automotive, construction, and machinery. We strive to deliver high-quality, cost-effective, and timely solutions tailored to customer needs.