Oem Customization Laser Cutting Processing Service Sheet Metal Manufacturing Metal Frame

We specialize in OEM customization and laser cutting processing for a wide range of sheet metal manufacturing service requirements. Our solutions include the development and production of durable, precisely formed metal frames suitable for various industrial environments. We integrate advanced laser cutting with expert sheet metal manufacturing service to deliver reliable and tailored fabrication outcomes.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

1. Advanced Sheet Metal Manufacturing Service Capabilities

We offer sheet metal manufacturing service that includes laser cutting, bending, forming, and frame assembly. Our laser cutting machines enable clean edges, tight tolerances, and minimal thermal distortion. This precision lays the groundwork for accurate downstream operations and structural reliability in all frame-based assemblies.

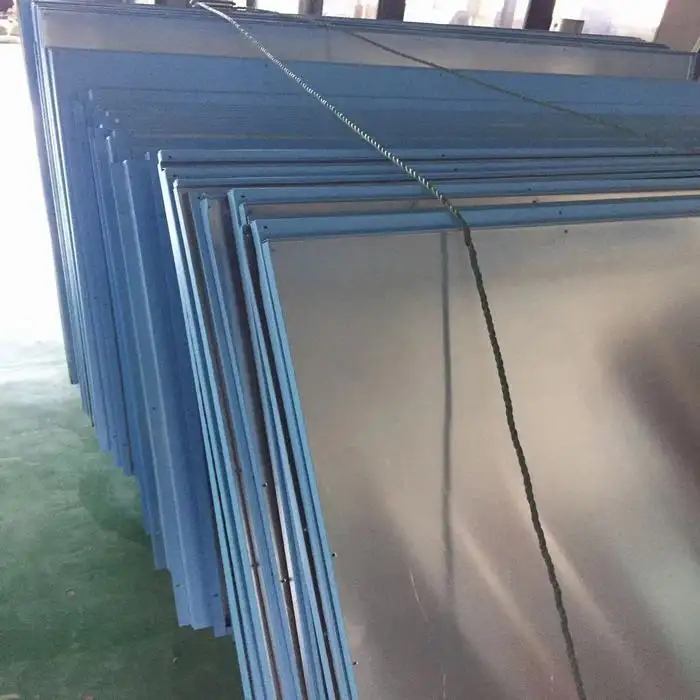

2. Custom Metal Frame Fabrication

We create custom metal frames tailored to fit different functional and structural requirements. Our sheet metal manufacturing service supports flexible frame design, allowing modifications in geometry, joint configuration, and mounting features. These frames are commonly used in mechanical equipment, industrial shelving, and architectural support systems.

3. Material Adaptability and Application Flexibility

Our sheet metal manufacturing service works with a wide selection of materials including stainless steel, carbon steel, and aluminum alloys. This versatility allows us to support a variety of applications across construction, transportation, electronics, and machinery sectors. Each material is processed using optimal cutting and forming parameters to maintain performance characteristics.

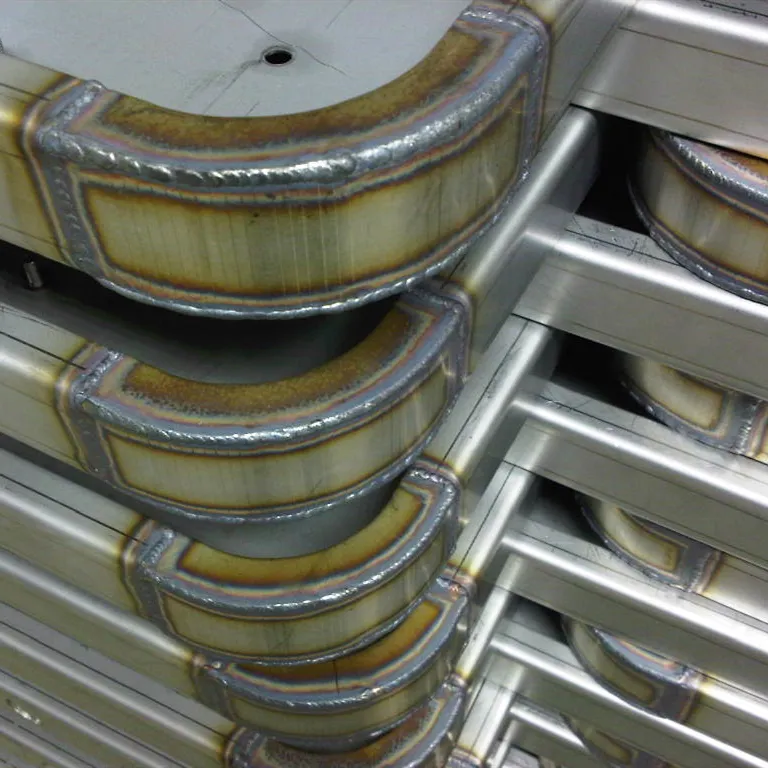

4. Welding and Assembly Integration

We combine our sheet metal manufacturing service with professional welding capabilities to deliver fully assembled metal frames. Whether the design involves spot welding, MIG/TIG welding, or structural joining, we ensure consistent assembly performance suitable for operational loads and environmental exposure.

5. Efficient Workflow and Customization Support

Our sheet metal manufacturing service emphasizes quick turnaround and high customization flexibility. With CNC-controlled equipment and digital fabrication systems, we accommodate both low-volume prototypes and high-volume production runs. This efficiency allows us to serve a wide range of customer needs while maintaining consistent product integrity.

Service Scope

We provide sheet metal manufacturing service that includes design adaptation, material processing, precision fabrication, and frame assembly. Our service covers industries such as manufacturing, automation, transportation, and infrastructure equipment.