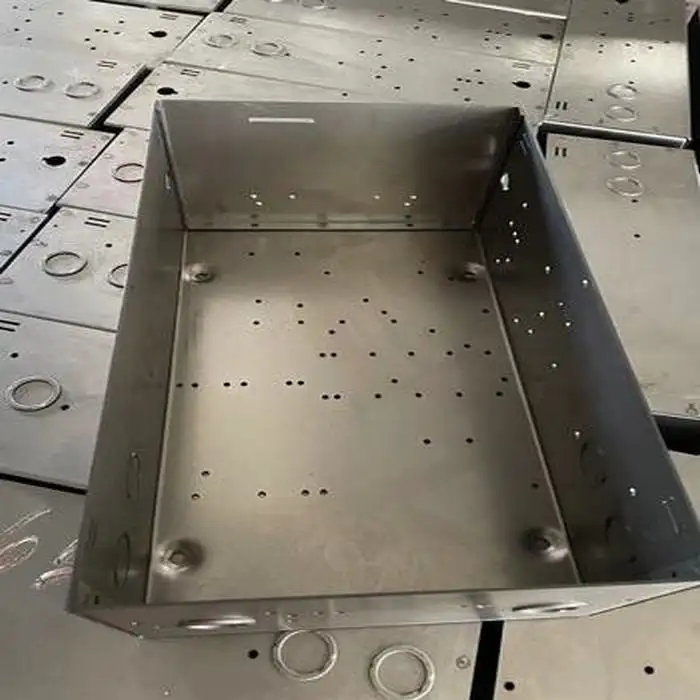

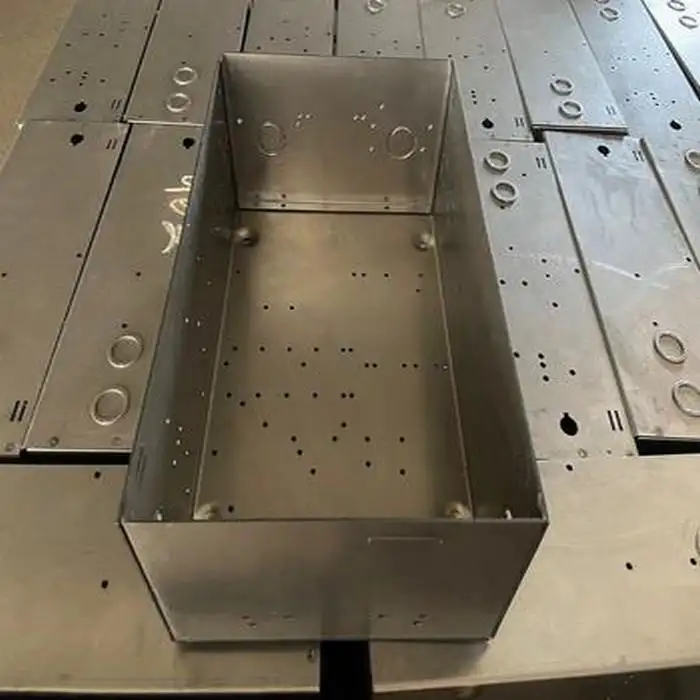

Oem Factory Laser Cutting Processing Service Sheet Metal Forming Welding Fabrication Metal Case

We provide OEM factory-level laser cutting processing and sheet metal forming service for a wide range of industrial applications. Our metal case solutions are achieved through a combination of precise cutting, forming, and welding techniques. With rich experience and advanced technology, we deliver custom-made metal structures tailored to clients’ specific design and performance needs.

Key attributes

Other attributes

Packaging and delivery

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

1. Integrated Sheet Metal Forming Service Capabilities

Our sheet metal forming service is designed to handle various forming tasks such as bending, drawing, flanging, and hemming. We employ CNC-controlled press brakes and hydraulic forming machines to ensure the consistency and accuracy of each component. The integration of forming with laser cutting ensures a streamlined production workflow, increasing efficiency and part quality.

2. Custom Fabrication for Metal Cases

Each metal case is tailored using our sheet metal forming service to meet different structural and functional requirements. We adapt forming parameters to accommodate complex designs, including curved surfaces, angular edges, and multiple radii, ensuring the finished product fits seamlessly into larger assemblies.

3. Material Processing Versatility

Our sheet metal forming service supports a broad range of materials such as stainless steel, aluminum, carbon steel, and alloy plates. We apply optimized forming methods according to the material’s mechanical properties, ensuring durability and functionality in every finished case.

4. Precision Welding Integration

After the sheet metal forming service stage, we utilize TIG, MIG, and spot welding techniques to assemble the components into robust enclosures. The combination of precision forming and welding guarantees strength and stability for cases used in electronics housings, control panels, and mechanical covers.

5. Surface Treatment and Post-processing

Following the core sheet metal forming service, we offer optional surface treatments such as powder coating, anodizing, and galvanization. These processes enhance the appearance, corrosion resistance, and lifespan of each metal case, making them suitable for use in both indoor and outdoor environments.

Service Scope

Our sheet metal forming service is part of a full-process metal fabrication solution that includes cutting, forming, welding, and final finishing. We support industrial sectors such as automation, energy, communication, transportation, and construction.