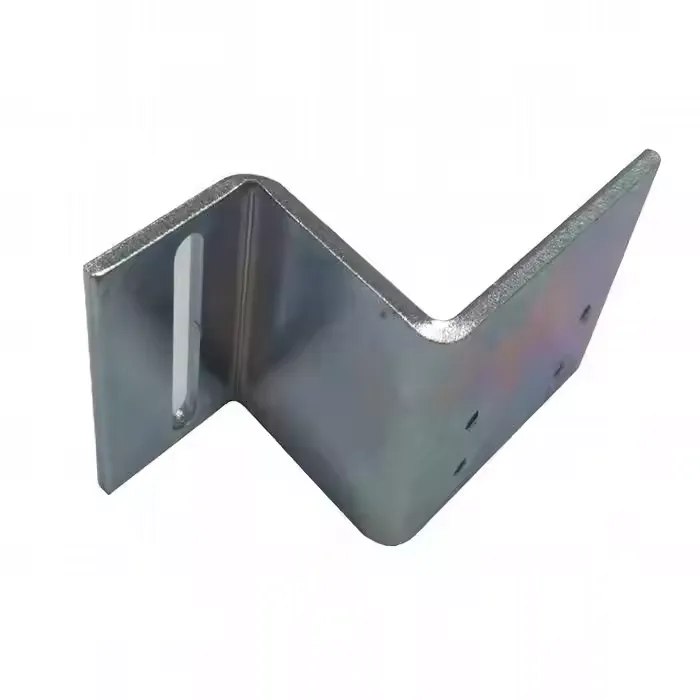

OEM Factory Precision Custom Sheet Metal Hardware Fabrication Stainless Steel Stamping Forming Parts

We specialize in providing precision sheet metal fabrication solutions with a focus on stainless steel stamping forming. Our factory supports customized production to meet a wide range of design and structural needs across industries like automotive, electronics, and machinery. Each component is processed using refined stamping and forming techniques tailored to specific application requirements.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

Comprehensive Sheet Metal Capabilities

We operate with an emphasis on stainless steel stamping forming, using integrated fabrication methods that control every stage—from material blanking to final forming. Our facility is designed to manage multiple shapes, wall thicknesses, and reinforcement needs with adaptability across different industries.

Tailored Engineering and Forming Strategy

We start every project by evaluating the final application. Our forming techniques are aligned with your technical drawings to ensure dimensional accuracy and proper mechanical function. Stainless steel stamping forming plays a central role in shaping brackets, panels, enclosures, and structural supports without sacrificing integrity.

Consistent Quality Across Multiple Batches

Our approach to stainless steel stamping forming is centered on batch consistency. We maintain tooling alignment and forming pressure standards throughout production to ensure that every part meets defined tolerances. Repeatability is especially important for assemblies and fixtures in mechanical or electrical environments.

Materials Fit for High-Precision Work

We work with multiple grades of stainless steel selected for their suitability in stamping forming. The material characteristics are matched to bending radii, pressing depths, and surface requirements. This ensures efficient transformation of raw material into final shapes through a controlled stainless steel stamping forming process.

High Accuracy with Controlled Deformation

Our methods reduce residual stress and warping by applying controlled force during stamping and forming. Tool paths and press timing are adjusted to accommodate complex geometries. Stainless steel stamping forming allows for sharp bends, clean transitions, and uniform surface finishes on visible and functional parts.

Production Flexibility and Rapid Adaptation

Whether your requirement is low-volume prototyping or large-scale OEM supply, our stainless steel stamping forming capacity adjusts to support each batch. Flexible workstations and modular fixtures help us shift between product models without production delays.

Application-Based Metal Component Solutions

We serve manufacturers in automotive, furniture, machinery, and industrial systems. The parts we create—through stainless steel stamping forming—include casings, chassis elements, mounting plates, and supporting frames, each adapted to the demands of its field usage.

Surface Condition and Optional Treatments

To improve corrosion resistance and visual finish, we offer additional processes such as oil coating, polishing, and powder coating. These surface options follow the stamping and forming steps to preserve dimensional control and enhance durability.

Collaborative Development Process

We collaborate with clients during the stainless steel stamping forming phase to refine designs, propose modifications, and support efficiency improvements. Feedback integration ensures that production goals are met while reducing rework or scrap.