OEM Wholesale Good Price Stainless Steel Sheet Metal Fabrication Custom Sheet Metal Products

We provide professional OEM wholesale services specializing in stainless steel sheet metal fabrication frames designed to meet a wide variety of industrial applications. Our custom sheet metal products focus on delivering durable, precise, and cost-effective framing solutions for structural and mechanical uses.

Key attributes

Other attributes

Lead time

| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 30 | To be negotiated |

| Tooling/Molding | Progressive Stamping Tooling or Single Stamping Tooling,or Robot stamping tooling |

| Drawing Format | DWG, PDF, DXF, STEP, IGS, JPG etc. |

| Materials | Spring Steel, Carbon Steel, Stainless Steel, Aluminum, Brass, etc 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper |

| Thickness | 0.3 -15 mm |

| Surface Finish | Heat Treatment, Plating, Powder Coating, Electrophoresis, Anodizing, HDG, Decromet |

| Tolerance | As requests |

| Certificates | ISO 9001:2015 |

| Process | Blanking, Stamping, Forming, Welding, Packing, Shipping |

| Packing | Carton Box + Plywood Pallet, Plywood Box with Plastic bag |

| Capacity | 500,000pcs / Week, Depends on specific parts |

| QC system | PPAP, FAI, IPQC, FIQC |

| Shipping | Shanghai / Ningbo port, Air shipping is also OK |

| Industries served | Furniture, Agricultural machinery, Sports, Homes,Solar Energy, Construction etc, |

1. Material Quality and Selection

Our stainless steel sheet metal fabrication frames are made from carefully selected materials known for excellent corrosion resistance and mechanical strength. This ensures the frames maintain structural integrity and longevity even under demanding environmental conditions.

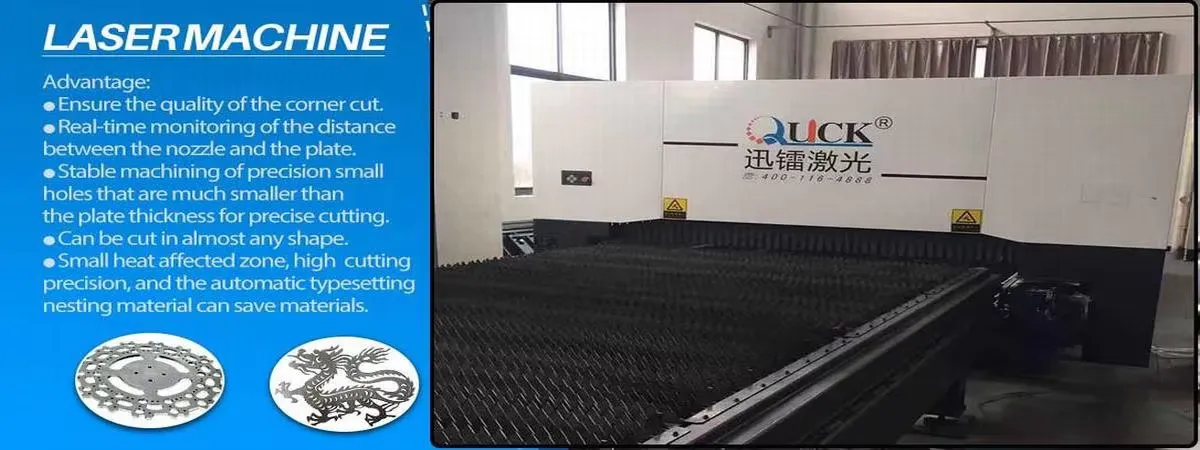

2. Precision Fabrication Techniques

We employ advanced CNC laser cutting, stamping, and bending processes to manufacture sheet metal fabrication frames. These techniques allow us to achieve precise dimensions, consistent quality, and intricate designs, fulfilling the requirements of complex industrial projects.

3. Customization and Versatility

Our services offer full customization, allowing clients to specify frame sizes, thicknesses, and design details. Whether for prototype development or mass production, we maintain high consistency and flexibility to suit different production scales and project needs.

4. Assembly and Structural Integrity

The sheet metal fabrication frames we produce undergo professional assembly and welding to ensure structural soundness. Our welding methods maintain the frame’s corrosion resistance and provide reliable mechanical connections vital for stable constructions.

5. Surface Treatment and Finishing

To enhance durability and aesthetics, we provide surface finishing options including polishing and protective coatings. These finishes contribute to increased wear resistance and help maintain the frames’ appearance over time.

Service Scope

Our OEM wholesale capabilities cover multiple sectors including automotive, electronics, construction, furniture, and machinery assembly. We emphasize competitive pricing paired with reliable lead times, ensuring our sheet metal fabrication frames meet diverse market demands.